In the rapidly evolving manufacturing landscape of Latin America, Brazil stands out as a high-potential market with unique demands, especially in industrial abrasives. For Henan Yode Superhard Tools Co., Ltd., winning the Brazilian high-end manufacturing supply chain was no accident. It was a meticulously crafted strategy combining localization, product innovation, and collaborative partnerships.

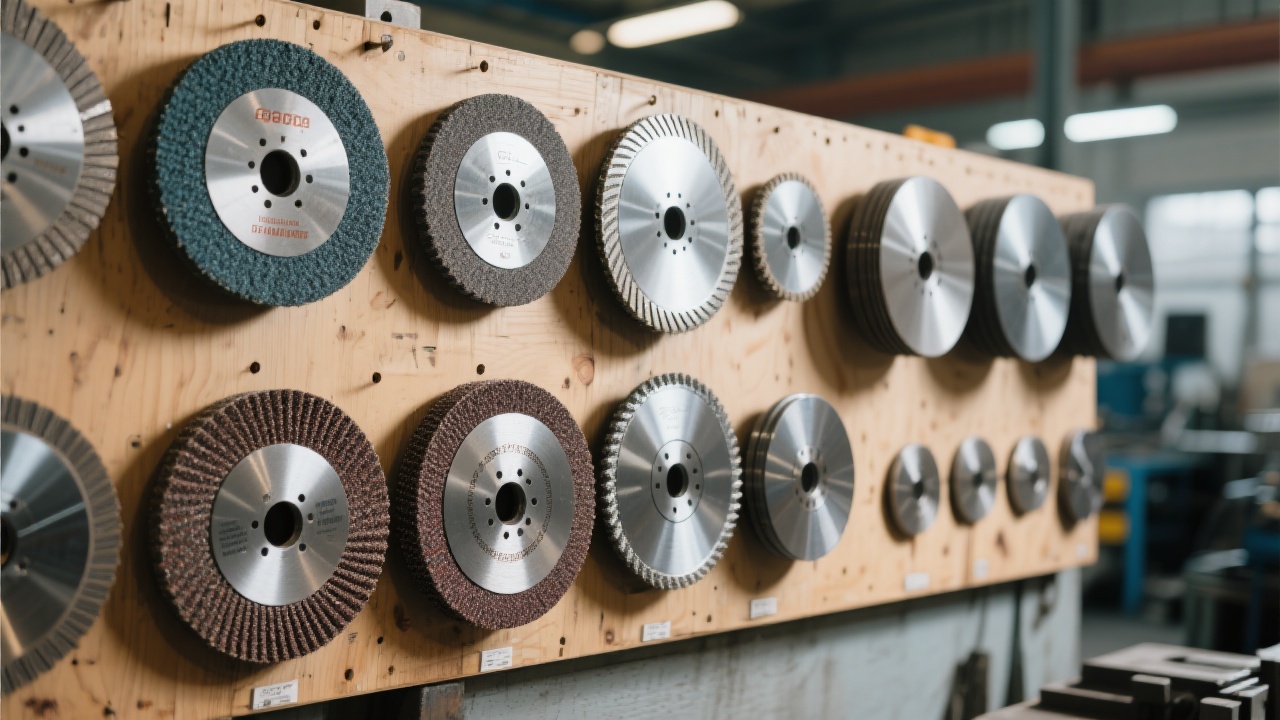

Before entering Brazil, Yode conducted exhaustive market research revealing precise challenges faced by local manufacturers. High demand for durable and efficient grinding solutions, especially for processing materials like stone and stainless steel, stood out prominently. Customers sought tools that not only endured harsh conditions but also delivered significant efficiency gains.

Based on client feedback, it became clear that existing tools fell short in longevity and speed. For example, Brazilian manufacturers processing granite and other stones required grinding wheels that could significantly reduce downtime and tool replacements.

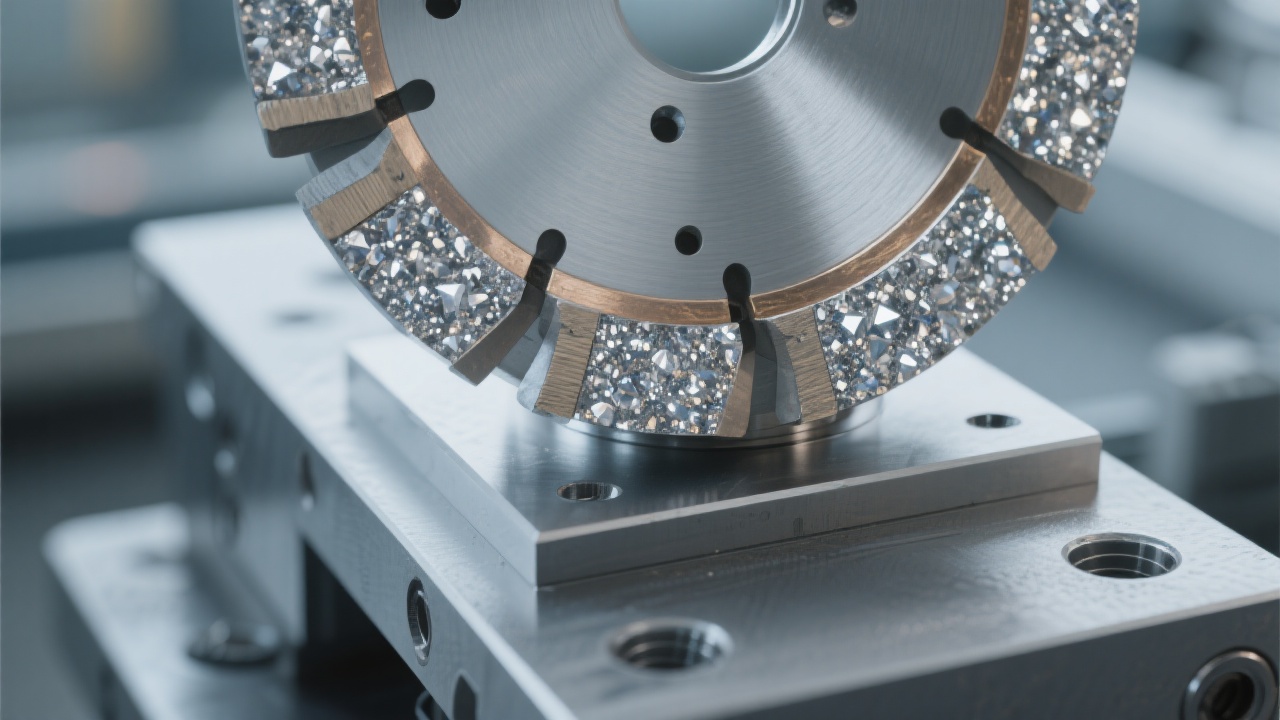

“Since switching to Yode’s cup-type brazed diamond grinding wheels, our processing line runs smoother and faster. We’ve seen a 30% boost in grinding efficiency and the tool life has extended by about 50%, dramatically cutting costs.” – Carlos M., Operations Manager, Brazilian Stoneworks Inc.

Armed with detailed market insights, Yode engineered its signature cup-type brazed diamond grinding wheels, available in 100-180mm diameters, to meet Brazilian industrial standards and material requirements. The customization focused on:

These targeted adjustments gave Yode a competitive edge, allowing Brazilian companies to process tougher materials faster while reducing tool wear.

Recognizing the importance of trust and timely support in the Brazilian market, Yode adopted a partnership model with local distributors that goes beyond logistics:

This collaboration model ensured a smooth customer journey, from inquiry to post-purchase, strengthening brand credibility.

.png)

Customer data shows remarkable improvements after adopting Yode’s products:

| KPI | Before Yode | After Yode | Improvement |

|---|---|---|---|

| Grinding Efficiency | 100 units/hr | 130 units/hr | +30% |

| Tool Life Span | 2000 cycles | 3000 cycles | +50% |

| Safety Incidents | 5 per year | 1 per year | -80% |

The brand’s proven performance has opened doors beyond Brazil, igniting interest in neighboring Latin American countries like Argentina and Chile, where industrial manufacturing growth is accelerating.