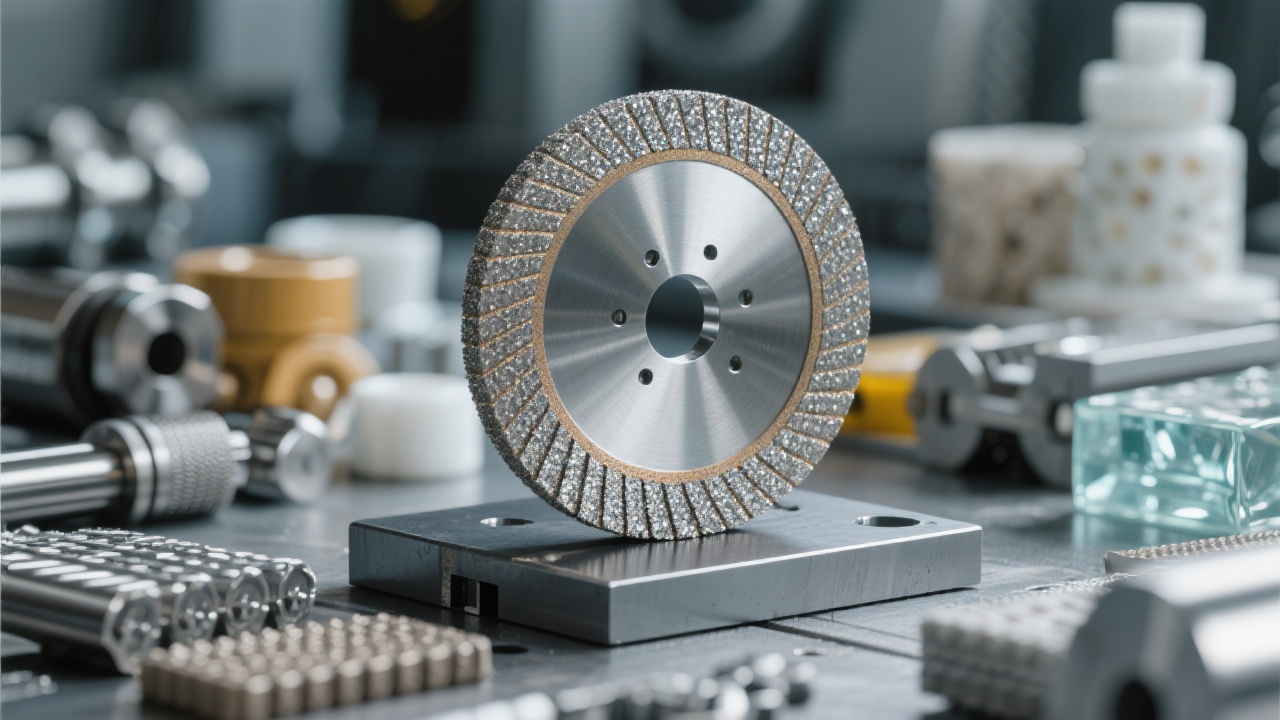

In the realm of high - end manufacturing, Youde Brazed Diamond Grinding Discs have emerged as the top choice. This article will conduct a comprehensive analysis of this product, from its innovative brazing technology to the selection of diamond particles and its overall performance.

Youde's brazing technology represents a significant leap forward compared to traditional welding methods. Traditional welding often has limitations in terms of bonding strength and thermal stability. However, Youde's innovative brazing technology can effectively enhance the bonding strength between the diamond particles and the substrate. Tests show that the bonding strength has been increased by approximately 30% compared to traditional methods. This improvement not only enhances the overall stability of the grinding disc but also significantly improves its thermal stability. As a result, the grinding disc can maintain its performance even under high - temperature and high - pressure working conditions, reducing the risk of diamond particles falling off during the grinding process.

The selection and distribution of diamond particles play a crucial role in the grinding efficiency and service life of the grinding disc. Youde carefully selects ultra - hard diamond particles, which are not only harder but also more wear - resistant. The scientific distribution of these particles on the grinding disc surface ensures that each diamond particle can effectively participate in the grinding process. Research indicates that with the optimized particle selection and distribution, the grinding efficiency of Youde's brazed diamond grinding discs has been increased by about 25% compared to ordinary grinding discs. At the same time, the service life has been extended by up to 40%, which means that users can achieve more grinding work with fewer replacements, significantly reducing the overall cost of use.

Youde's brazed diamond grinding discs have shown excellent performance in a wide range of materials, from cast iron to ceramics. In the processing of gray iron, the grinding disc can quickly remove the surface layer, achieving high - precision grinding. When it comes to stainless steel processing, its high - strength bonding and wear - resistant diamond particles can effectively avoid scratches on the stainless steel surface, ensuring the smoothness of the processed surface. In the case of ceramic processing, which is notoriously difficult, the grinding disc can still maintain high efficiency and accuracy. A comparison of processing different materials shows that Youde's grinding discs can save about 30% of processing time compared to traditional grinding tools.

Safety is a top priority in industrial production. Youde's brazed diamond grinding discs are designed with multiple safety features. The anti - stamping design can effectively resist the impact force generated during the grinding process, reducing the risk of disc damage. The anti - fracture structure ensures that the grinding disc will not break easily, protecting the safety of operators and equipment. According to user feedback, the safety design has significantly reduced the occurrence of safety accidents during the grinding process, providing a more reliable working environment for industrial production.

Based on user feedback and test data, Youde's brazed diamond grinding discs have demonstrated excellent stability and cost - effectiveness in long - term use. In a long - term grinding test, the grinding disc maintained a stable grinding performance throughout the test period, with a wear rate that was only about 60% of that of ordinary grinding discs. This means that users can achieve the same grinding effect with a lower frequency of replacement, which not only saves costs but also improves production efficiency. Choosing Youde is not just about selecting a tool; it's about choosing a reliable production partner, allowing every grinding operation to be safer and more efficient.

In conclusion, Youde Brazed Diamond Grinding Discs, with their advanced technology, excellent performance, and safety features, are the ideal choice for high - end manufacturing. If you are looking for a high - quality industrial grinding solution, click here to learn more about Youde's brazed diamond grinding discs.