Brazed diamond grinding wheels have emerged as a fundamental component in precision grinding applications, offering remarkable wear resistance and efficiency enhancements. This article explores the technical principles underlying these tools, the distinct demands across industries, and strategic approaches for selecting optimal grinding wheels to drive productivity and sustainable manufacturing.

At the core of brazed diamond grinding wheels lies a metallurgical bonding process where diamond grit is attached to a steel core using a high-temperature copper or silver alloy braze. Compared to resin or vitrified bonded wheels, brazed wheels exhibit significantly higher thermal conductivity and mechanical strength. These characteristics translate into superior grit retention and markedly improved wear resistance.

Quantitatively, brazed diamond wheels can endure >30% longer service life under comparable grinding conditions, reducing tool changes by up to 25%. This results in less downtime and more consistent part quality. Furthermore, the open structure of the brazed bond facilitates effective coolant penetration and chip clearance, decreasing grinding burns and improving surface finish.

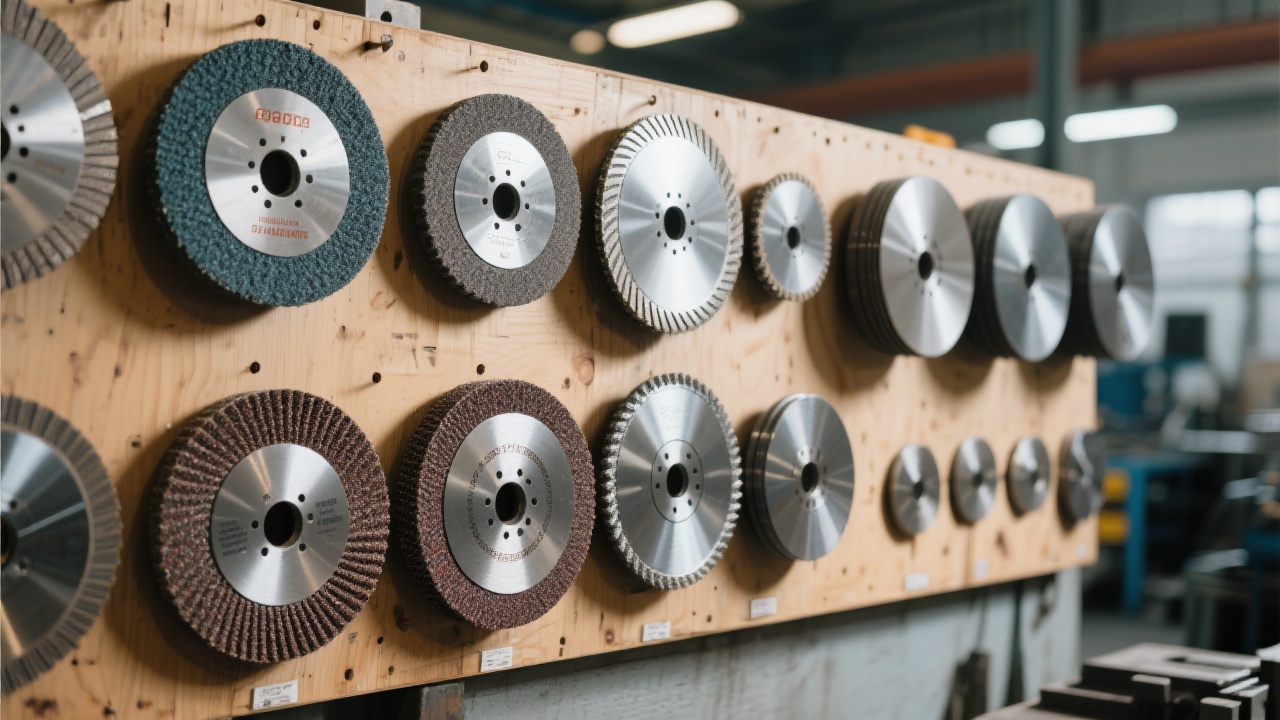

Different sectors impose unique requirements on grinding tools, influenced by the materials processed and desired outputs:

The 400-series brazed diamond wheels are engineered for demanding metal grinding applications. Featuring fine diamond grit sizes (typically 100–300 mesh), these wheels excel at machining hardened steels and superalloys such as Inconel and titanium alloys.

| Parameter | Typical Value | Benefit |

|---|---|---|

| Diamond Grit Size | 150 Mesh | Balances surface finish and material removal rate |

| Bonding Alloy | Copper-Silver Brazing | Enhances thermal conductivity & grit retention |

| Wheel Diameter | 150-300 mm | Adaptable to various grinding machines |

Mold manufacturing demands grinding wheels capable of delivering micron-level surface finishes and geometric accuracy. Brazed diamond wheels address core challenges by reducing surface micro-cracks through consistent grit exposure and stable cutting, enabling improved mold life and decreased polishing time by approximately 20%.

Vibration damping achieved through brazed bonding reduces chatter marks, a common cause of rejected parts. The wheels’ ability to sustain sharp diamond edges significantly increases grinding ratio, allowing manufacturers to operate at higher speeds while maintaining tight tolerance control.

The ceramics industry faces rigorous standards regarding dust emission and environmental impact. Brazed diamond wheels’ open structure and efficient coolant interface contribute to lower dust generation and thermal stress, leading to reduced micro-fractures in ceramic parts.

Additionally, the wheels’ longevity — often doubling the lifespan compared to resin-bonded counterparts — minimizes waste and replacement frequency, aligning with green manufacturing imperatives. Some advanced brazed wheels have achieved ISO 14001 certification, attesting to their eco-friendly manufacturing processes.

To establish technical credibility and safety compliance, brazed diamond grinding wheels are commonly certified against standards such as ISO 9001 for quality management and ISO 14001 for environmental management. Moreover, adherence to ANSI B7.1 guidelines ensures operator safety and reliable mechanical performance.

Manufacturers also provide detailed datasheets including metallurgical composition, grit analysis, and performance test results to support customer technical evaluations.

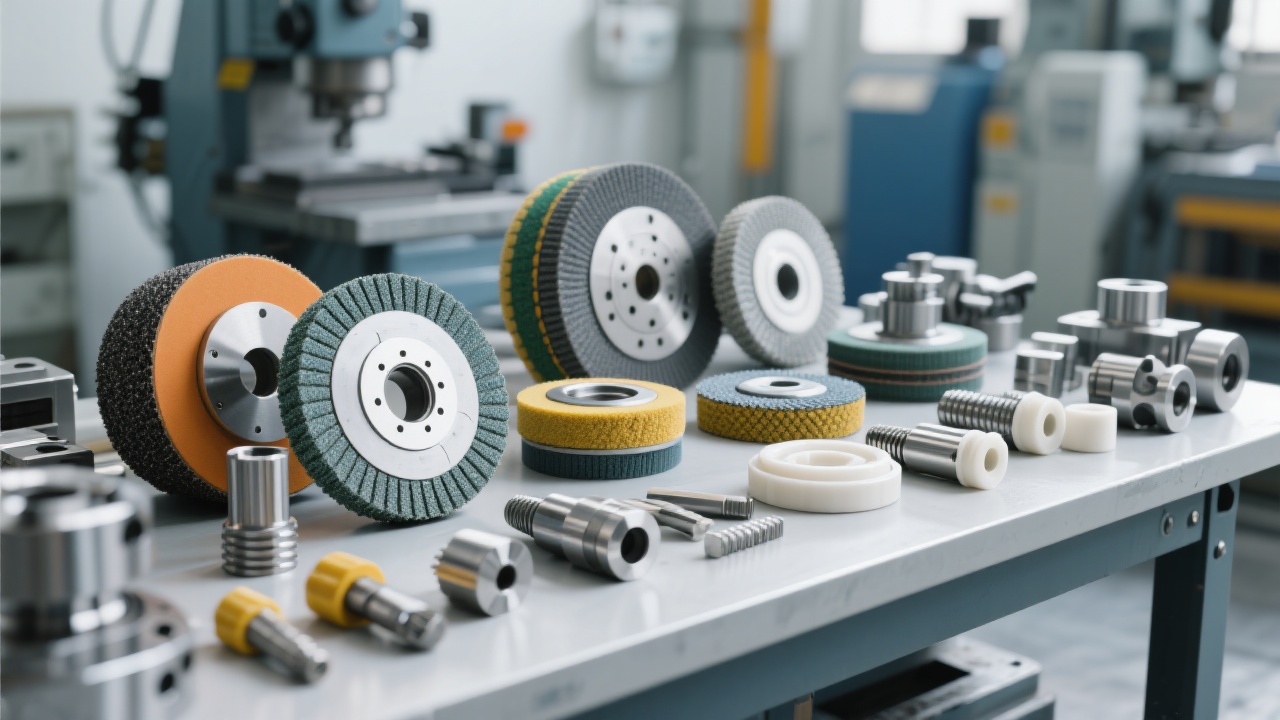

When choosing brazed diamond grinding wheels, consider the following parameters:

Partnering with suppliers offering custom wheel configurations and technical support can further optimize your grinding process for better profitability and sustainable operations.