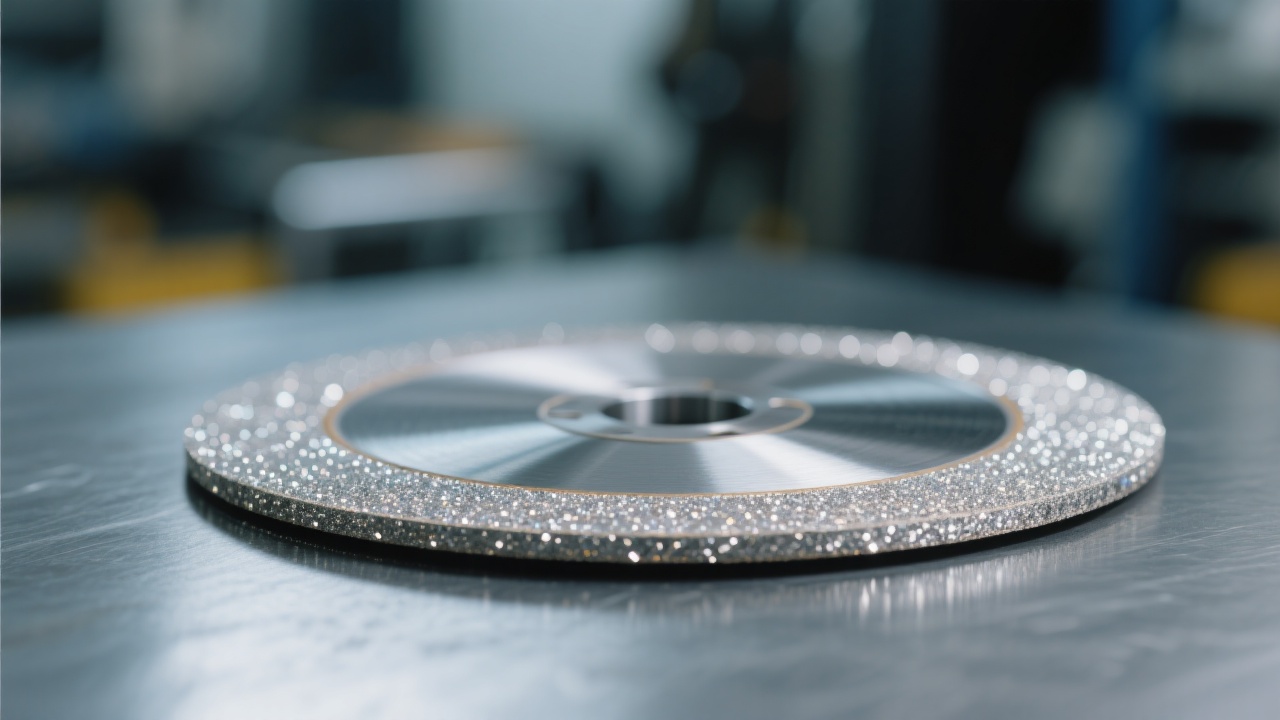

In industrial manufacturing, custom diamond grinding wheels play an essential role, especially when dealing with complex or irregularly shaped workpieces. For engineers and procurement professionals engaged in high-precision grinding tasks, understanding the nuances of non-standard grinding wheel design, material selection, and processing is crucial to achieving consistent, efficient results. The following exploration dives into the top concerns foreign trade B2B customers raise about non-standard grinding wheels — accompanied by professional guidance to help you avoid common pitfalls.

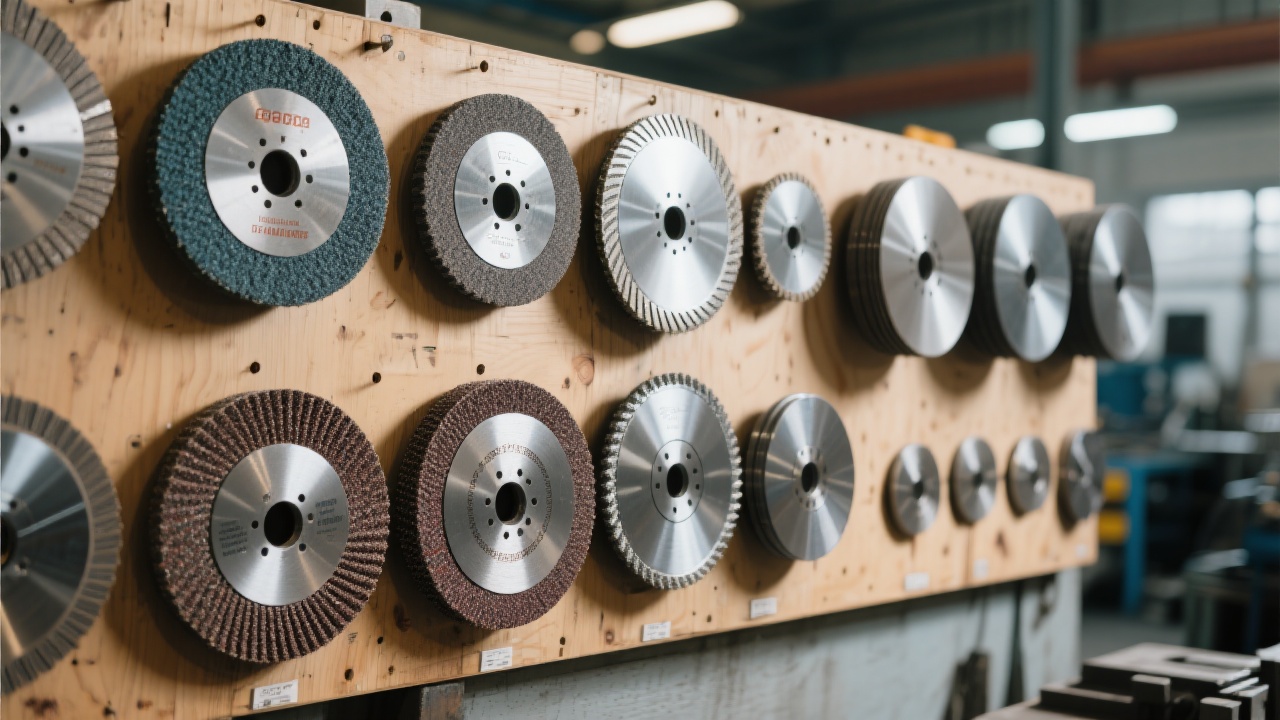

Non-standard grinding wheels deviate from traditional specifications to accommodate individualized shapes, sizes, and abrasive properties. This customization is vital for operations requiring:

The non-standard approach empowers manufacturers to tailor grinding wheels specifically to the demands of materials like ceramics, composites, and superhard metals — boosting accuracy and product lifespan.

A comprehensive design process begins with thoroughly understanding customer requirements, including:

| Step | Key Focus |

|---|---|

| Requirements Gathering | Analyzing workpiece geometry, material hardness, and processing tolerance |

| Material Selection | Choosing diamond grit attributes and bonding agents for optimal wear resistance |

| Thermal Deformation Control | Incorporating compensation techniques to minimize dimensional deviation caused by heat |

| Dressing and Truing | Ensuring uniform abrasive surface for consistent grinding quality |

Thermal deformation remains a significant challenge during high-speed grinding. Accurate prediction and compensation using computer-aided design tools and careful bonding formulation are essential to prevent shape distortions.

Several industries benefit from expertly engineered non-standard grinding wheels:

In each scenario, meticulous parameter setting — such as grit size, bond type, and wheel geometry — directly influences the balance between productivity and wheel lifespan.

"What are the biggest challenges your team faces with non-standard grinding wheels?"

Share your experiences — whether it’s issues with design, thermal effects, or dressing processes — and get tailored insights from our expert team.

Common errors such as incorrect parameter settings, uneven wheel dressing, and neglecting thermal influences can severely impact grinding outcomes. Implementing these best practices can elevate your grinding wheel customization:

These approaches foster agility in customized wheel production, translating into higher workpiece quality and consistent performance.

Successfully navigating the complexities of non-standard diamond grinding wheels requires more than just component supply — it involves adoption of a flexible design mindset. This framework encourages continuous feedback loops, adaptive parameter tuning, and proactive troubleshooting.

Enhance your team’s capabilities with our exclusive Non-Standard Grinding Wheel Design & Pitfall Avoidance Guide. This practical manual offers step-by-step methodologies, real case studies, and actionable checklists to empower precision manufacturing.

Remember, with our expertise: "Your drawings, we understand. Every customization, more precise and efficient."