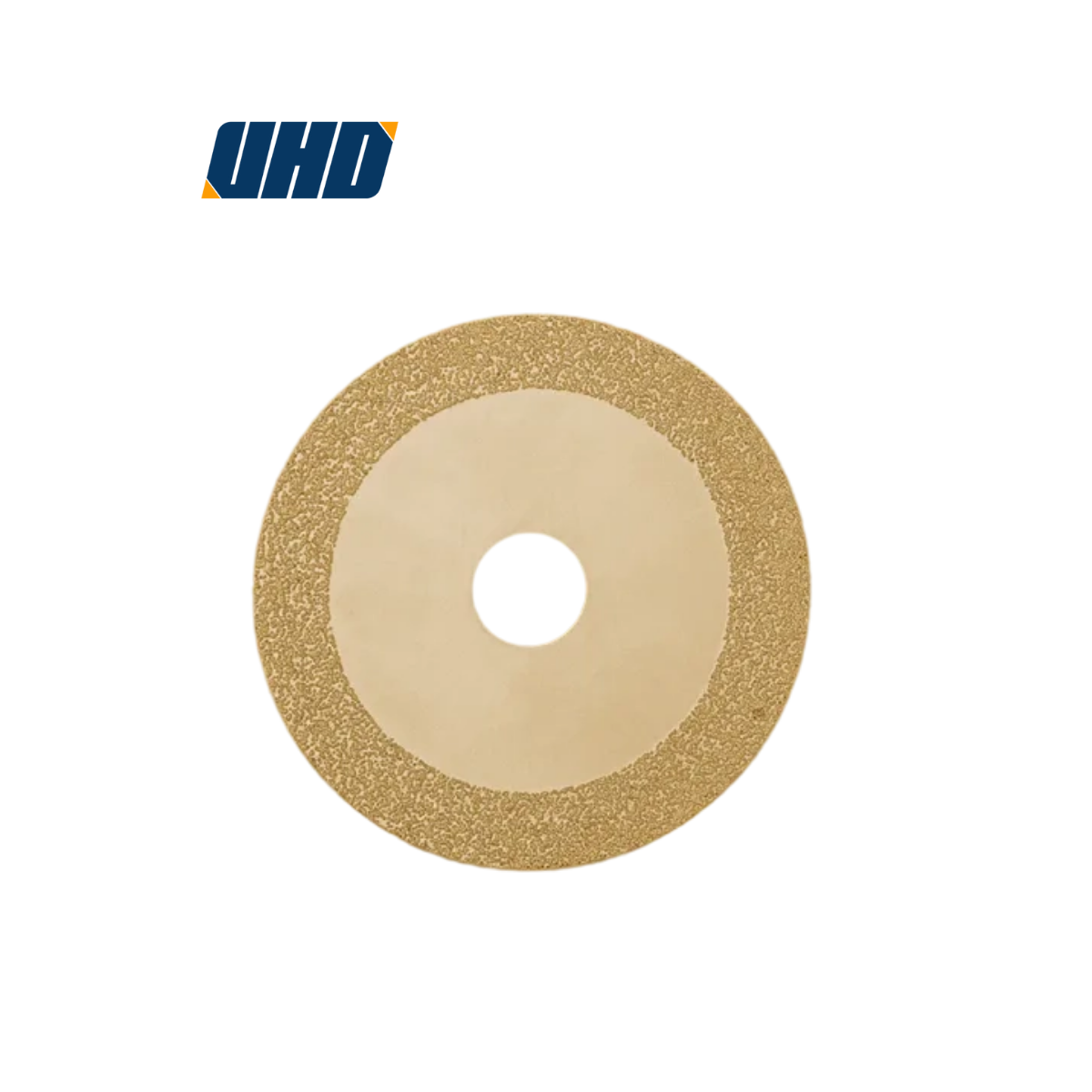

Brazing technology plays a crucial role in elevating the performance of diamond grinding discs. By firmly bonding diamond particles to the substrate, brazing significantly improves the retention of diamonds, enhancing the overall cutting ability and wear - resistance of the grinding discs. For instance, compared with traditional electroplated diamond grinding discs, brazed diamond grinding discs can increase the cutting efficiency by up to 30% according to industry data. This is because the high - strength bond formed by brazing allows the diamond to withstand greater forces during the grinding process without falling off easily.

In grey iron processing, brazed diamond grinding discs have shown outstanding performance. Grey iron is a hard and brittle material, and traditional grinding tools often face problems such as rapid wear and poor cutting quality. However, brazed diamond grinding discs can maintain a sharp cutting edge throughout the process. A case study of a manufacturing plant showed that when using brazed diamond grinding discs, the wear rate was reduced by 25% compared to other grinding tools, and the surface finish of the grey iron parts was significantly improved.

Stainless steel is known for its toughness and corrosion - resistance. Brazed diamond grinding discs can effectively cut through stainless steel with high precision. The strong bond between the diamond and the substrate prevents the diamond from being pulled out by the tough stainless - steel material. In a real - world scenario, a metalworking shop reported that using brazed diamond grinding discs in stainless - steel processing increased the productivity by 20% and reduced the frequency of tool replacement.

Ceramic materials are extremely hard and brittle. Brazed diamond grinding discs are well - suited for ceramic processing as they can provide a smooth and precise cut. A ceramics factory found that the use of brazed diamond grinding discs reduced the breakage rate of ceramic products during grinding by 30%, ensuring higher product quality and lower production costs.

.png)

Many users have shared their positive experiences with brazed diamond grinding discs. One professional mechanic, John, said, "I've been using these brazed diamond grinding discs for a while now. Their durability is amazing. I used to replace grinding discs frequently, but with these, I can work for much longer periods without having to worry about tool failure. And the safety features, like the anti - kickback design, give me peace of mind during operation."

The anti - impact design of brazed diamond grinding discs is a key factor in extending their service life. When grinding hard materials, the discs are often subjected to strong impacts. The anti - impact design, such as the use of shock - absorbing layers and reinforced structures, can effectively reduce the damage caused by impacts. For example, a well - designed anti - impact structure can increase the disc's resistance to impacts by up to 40%, thereby prolonging its service life.

Proper size adaptation is also crucial. Using a grinding disc with the right size for the specific processing task can ensure optimal performance. An oversized or undersized disc may not fit well with the grinding equipment, leading to uneven wear and reduced efficiency. A study showed that using a correctly sized brazed diamond grinding disc can increase the service life by 15%.

To make the most of brazed diamond grinding discs, it is important to follow some practical operation suggestions. First, always check the disc for any damage before use. Second, use the appropriate grinding speed and pressure according to the material being processed. Common mistakes to avoid include over - speeding the disc, which can cause excessive wear, and using the disc on materials it is not designed for. By following these guidelines, users can ensure the safe and efficient use of the grinding discs.

Youde's brazed diamond grinding discs stand out in the industry for their high efficiency, durability, and safety. With advanced brazing technology, well - designed structures, and a focus on user needs, Youde products can significantly improve the processing efficiency and extend the service life of the grinding tools. Whether you are a professional mechanic or a manufacturing industry practitioner, choosing Youde's brazed diamond grinding discs means choosing a reliable solution for your grinding needs. "Durability is the hard truth" is not just a slogan but a commitment that Youde has always adhered to. Explore Youde's brazed diamond grinding discs now and experience the difference!