In the high - precision machining field, brazed diamond grinding discs have emerged as the top choice. But what makes them so special? Let's delve into the details.

Brazing technology represents a significant leap forward compared to traditional welding methods. The bonding strength between the diamond particles and the substrate is greatly enhanced, leading to a remarkable improvement in wear resistance and stability. Tests have shown that brazed diamond grinding discs can maintain their cutting performance up to 30% longer than those made with traditional welding. This means fewer replacements and lower costs in the long run.

In the mechanical manufacturing industry, a user from a large - scale machinery factory shared his experience. "We used to struggle with frequent disc replacements when grinding cast iron parts. Since switching to Youde's brazed diamond grinding discs, our production efficiency has increased by 25%. The discs can handle high - volume grinding tasks without losing their sharpness quickly," he said. In the building materials processing sector, a stone processing company found that these discs could effectively reduce the surface roughness of marble slabs, improving the overall quality of their products.

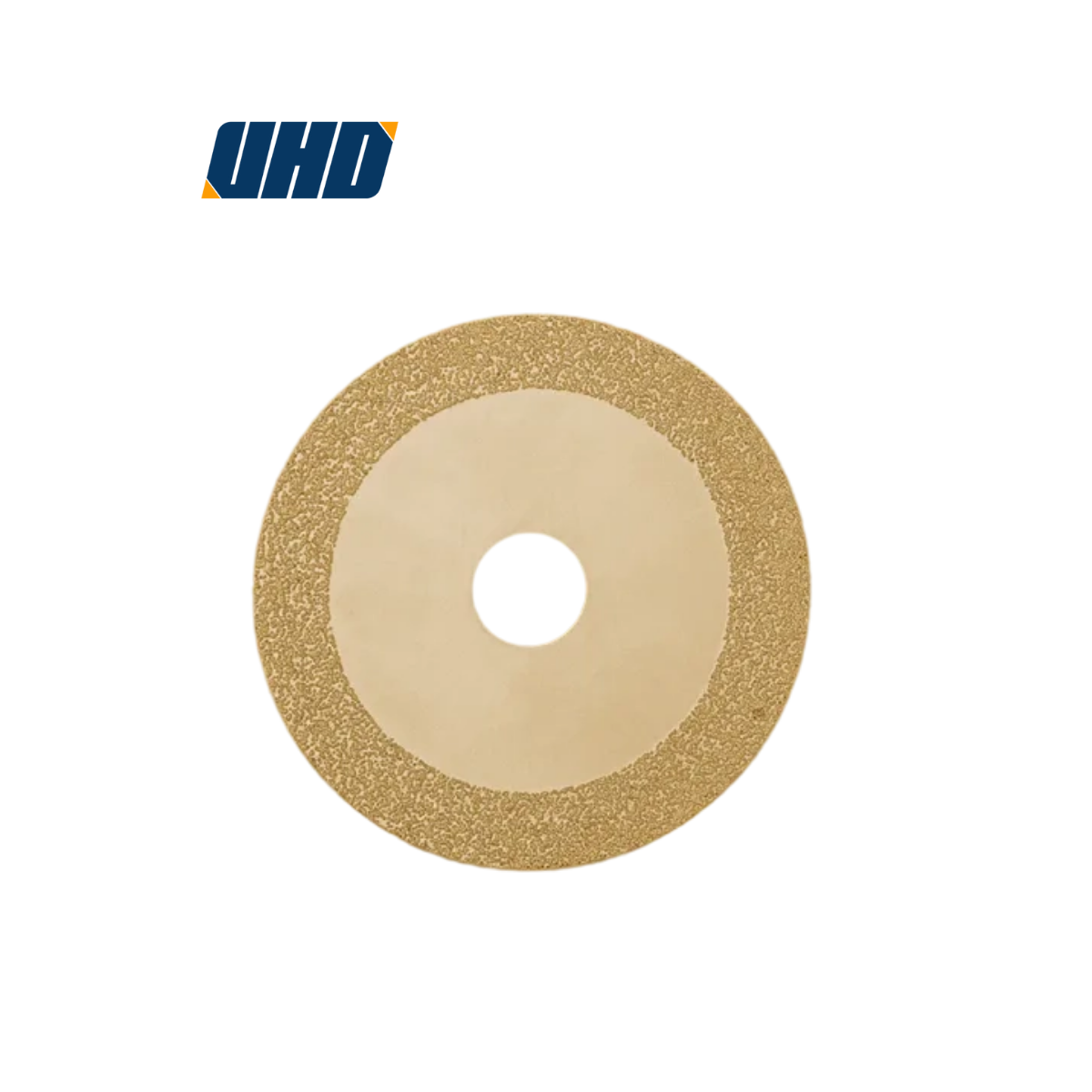

Youde offers brazed diamond grinding discs in a variety of sizes, ranging from 100mm to 180mm, and different shapes such as flat and curved. This wide range of options allows them to adapt to diverse working conditions. Whether it's a small - scale precision grinding job or a large - area rough grinding, there is a suitable disc available. For example, the 100mm flat disc is ideal for fine - tuning small components, while the 180mm curved disc can cover more surface area during stone polishing.

Safety is a top priority in any machining operation. Youde's brazed diamond grinding discs are designed with anti - fracture and anti - impact features. The anti - fracture design reduces the risk of disc breakage during high - speed rotation, protecting operators from potential injuries. A study indicated that the anti - impact design can withstand sudden shocks up to 20% more effectively than standard grinding discs. This not only safeguards the operators but also reduces the likelihood of damage to the workpiece.

The core advantages of Youde's brazed diamond grinding discs can be summarized as high efficiency, safety, and long service life. These factors combined lead to sustainable cost optimization. By improving grinding efficiency, reducing replacement frequency, and protecting operators, the overall production cost can be significantly reduced. In fact, some users have reported a 20% reduction in their annual grinding - related costs after using these discs.

| Grinding Disc Type | Grinding Efficiency (per hour) | Service Life (hours) |

|---|---|---|

| Traditional Grinding Disc | 10 units | 20 |

| Youde Brazed Diamond Grinding Disc | 13 units | 26 |

As shown in the table, Youde's brazed diamond grinding discs outperform traditional ones in both grinding efficiency and service life.

In conclusion, Youde's brazed diamond grinding discs are not just more durable; they are the starting point for a significant efficiency leap. Choosing the right grinding tool is the key to real cost - reduction and efficiency improvement. Your processing scenario may require a specific model. Click here to find out which one is suitable for you!