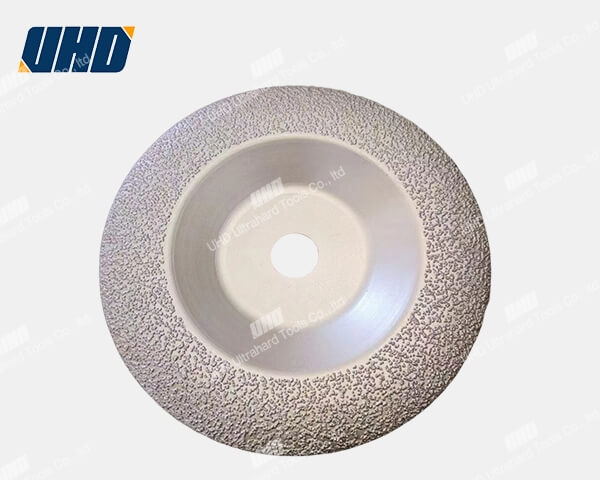

Brazed diamond grinding tools have emerged as a revolutionary solution in the field of industrial grinding. These tools are designed with unique features that set them apart from traditional grinding tools. Their base performance is characterized by high precision and exceptional durability. The design of brazed diamond grinding tools involves advanced manufacturing techniques that ensure the firm bonding of diamond particles to the tool substrate, which is crucial for maintaining the tool's shape and performance during high - intensity grinding operations.

The technical parameters of brazed diamond grinding tools play a vital role in determining their grinding effectiveness. For example, the grit size of the diamond particles directly affects the surface finish of the workpiece. A smaller grit size generally results in a smoother surface finish, which is ideal for applications where high precision is required, such as in the manufacturing of optical components. On the other hand, a larger grit size can remove material more rapidly, making it suitable for rough grinding operations.

The bond strength between the diamond particles and the substrate is another critical parameter. A strong bond ensures that the diamond particles do not fall off easily during grinding, which is essential for maintaining the tool's sharpness and durability. The concentration of diamond particles also impacts the grinding performance. A higher concentration can lead to faster material removal rates, but it may also increase the cost of the tool. Therefore, finding the right balance between these parameters is crucial for achieving optimal grinding results.

When it comes to grinding high - hardness materials such as gray iron, stainless steel, and ceramics, there are several challenges. Gray iron has a graphite structure that can cause the tool to wear quickly due to its abrasive nature. Stainless steel is known for its toughness, which makes it difficult to grind without causing excessive heat generation. Ceramics are extremely hard and brittle, and improper grinding can lead to cracks and chipping.

To address these challenges, specific brazed diamond grinding tools are required. For gray iron, tools with a high - strength bond and a medium grit size are recommended to ensure efficient material removal and long tool life. For stainless steel, tools with good heat - dissipation properties are essential to prevent overheating and tool wear. When grinding ceramics, tools with a fine grit size and a gentle grinding action are needed to minimize the risk of cracking and chipping.

.png)

In industrial applications, brazed diamond grinding tools have demonstrated their high - efficiency and durability. For instance, in a manufacturing plant that produces automotive parts, the use of brazed diamond grinding tools for grinding gray iron components has increased the production efficiency by 30%. The tools were able to maintain their sharpness for a longer period, reducing the frequency of tool replacement and thus saving both time and cost.

In another case, a company specializing in the production of stainless - steel kitchenware used brazed diamond grinding tools to improve the surface finish of their products. The tools were able to achieve a mirror - like finish on the stainless - steel surface, enhancing the aesthetic appeal of the products and increasing their market competitiveness.

Customers who have used the brazed diamond grinding tools from Henan Youde Superhard Tools Co., Ltd. have provided positive feedback. One customer, a manager of a machinery manufacturing company, said, "Since we started using Henan Youde's brazed diamond grinding tools, our production efficiency has significantly improved. The tools are very durable and can handle high - hardness materials with ease. We have also noticed an improvement in the quality of our products, which has helped us gain more customers in the market."

These success stories not only enhance the credibility of the products but also strengthen the brand image of Henan Youde Superhard Tools Co., Ltd. They serve as real - world examples of how the tools can bring tangible benefits to industrial users.

When choosing a brazed diamond grinding tool for high - precision grinding, several key points should be considered. First, understand the specific requirements of your grinding application, including the type of material to be ground, the required surface finish, and the production volume. Second, pay attention to the technical parameters of the tool, such as grit size, bond strength, and diamond concentration. Third, look for tools with a proven track record of performance, preferably backed by customer feedback and case studies.

It is also advisable to consult with experts in the field or the tool manufacturer to get professional advice on tool selection. This can help you make a more informed decision and ensure that you choose the most suitable tool for your needs.

.png)

The future of grinding technology is promising, with several emerging trends. One of the trends is the development of more advanced brazing techniques that can further improve the bond strength between diamond particles and the substrate, leading to even more durable and efficient tools. Another trend is the integration of smart technologies into grinding tools, such as sensors that can monitor the tool's performance in real - time and provide feedback for optimization.

These trends present significant market opportunities for companies like Henan Youde Superhard Tools Co., Ltd. By staying ahead of the curve and investing in research and development, they can continue to offer high - quality products that meet the evolving needs of the industrial market. If you are looking for high - performance brazed diamond grinding tools to enhance your production efficiency and product quality, click here to explore Henan Youde's product range.