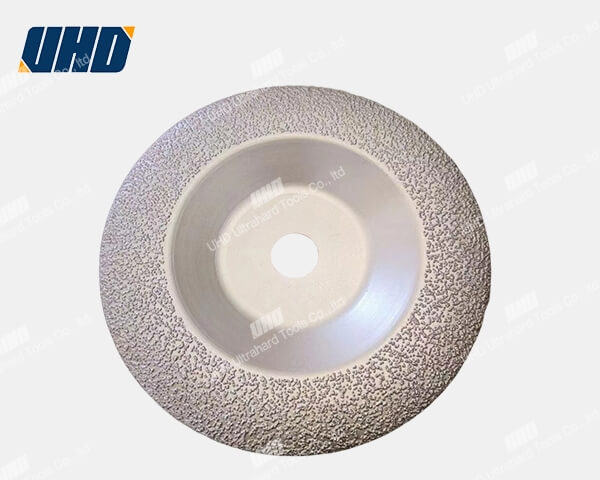

When tackling the grinding of ultra-hard materials such as gray cast iron, stainless steel, stone, or ceramics, selecting the right abrasive tool is critical. You will discover how brazed diamond grinding discs, crafted through advanced design theories combined with precision manufacturing processes, transform grinding performance — ensuring not only durability but also exceptional precision and safety.

The essence of brazed diamond grinding discs lies in balancing abrasive particle distribution and substrate bonding to achieve stable grinding over extended periods. Specifically engineered to meet the rigorous demands of high-hardness materials—including cast irons and ceramics—these discs maintain consistent sharpness while minimizing vibration and heat build-up.

You will find that the design optimizes diamond grain size and concentration to maximize material removal rate (MRR) without compromising surface finish quality. With precise grain placement and a metallurgically bonded matrix, the tool's cutting edges stay sharp, reducing the frequency of replacement and downtime.

The manufacturing process follows a series of highly controlled steps to ensure the disc’s robustness and performance:

| Process Stage | Critical Control Points | Impact on Product |

|---|---|---|

| Diamond Particle Selection & Distribution | Precise grain sizing and uniform surface layout | Optimizes cutting efficiency & consistent wear |

| Brazing Interface Strengthening | Metallurgical bonding under vacuum or controlled atmosphere | Enhances impact resistance and reduces particle loss |

| Thermal Treatment | Controlled cooling cycles to relieve stress and harden bonding alloy | Improves wear resistance and prolongs lifespan |

Compared to conventional welding, brazing creates a more uniform and metallurgically sound bond between the diamond particles and the disc substrate. This leads to superior shock absorption during heavy-duty grinding, reducing the incidence of premature tool failure.

In controlled factory tests, brazed diamond discs have demonstrated a 30% longer service life and 20% higher material removal rates on gray cast iron compared to tungsten inert gas (TIG) welded alternatives. This translates to measurable cost savings and improved operational uptime.

In a recent collaboration with a major mechanical factory specializing in ductile iron component machining, brass diamond grinding discs achieved a consistent grinding efficiency increase of 18%, while reducing disc wear rates by over 22%. Dimensional accuracy was maintained within a tight tolerance band of ± 0.1mm throughout production batches.

Beyond performance, clients emphasize the enhanced safety profile with brazing helping prevent cracks and unexpected disc failures, a common hazard with older welded tools. This aligns perfectly with today’s stringent workplace safety regulations.

With a clear focus on durability and precision, our brazed diamond discs embody the motto: “Not just durable, but precise.” Every disc is a result of meticulous engineering that ensures “every cut counts.” Our continuous investments in R&D and quality control mean sustained grinding stability and longevity you can depend on.

You deserve grinding tools that exactly match your operational expectations, and these advanced brazed diamond discs are engineered to deliver on that promise.

Unlock higher grinding productivity, improved tool longevity, and enhanced safety on your production lines. Discover the power of precision brazed diamond grinding discs now — and make every cut worth trusting.