.png?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

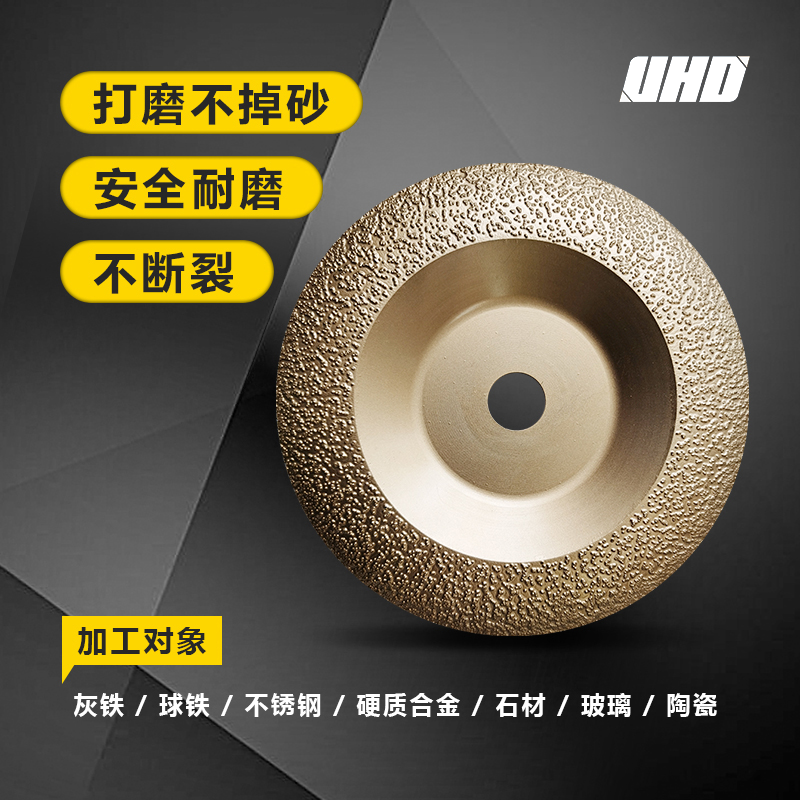

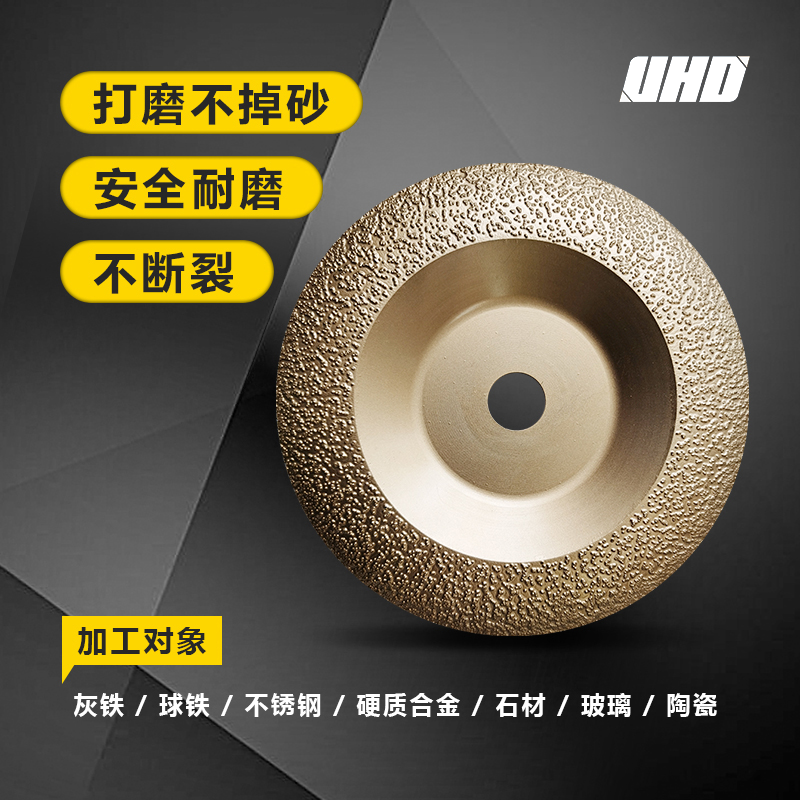

In today’s competitive manufacturing landscape, tool durability and processing efficiency can define the fine line between success and failure. The Sintered Diamond Grinding 100 from Henan Youde Superhard Tools Co., Ltd. exemplifies this principle, offering exceptional performance under high-load grinding conditions. Backed by extensive client feedback and real-world application cases, this specialized grinding tool redefines operational reliability and cost-effectiveness across materials like gray cast iron, stainless steel, and hard alloys.

The Sintered Diamond Grinding 100 integrates advanced bonding technologies with premium-grade diamond abrasives to achieve a robust yet finely-tuned balance of strength and wear resistance. Designed specifically for high mechanical stress environments, its proprietary sintering process ensures a dense matrix structure that prevents premature grain dislodgement, significantly extending tool lifespan. Precision engineering allows the grinding wheel to maintain sharpness after prolonged use, reducing downtime caused by tool replacement.

| Parameter | Value | Industry Benchmark |

|---|---|---|

| Bond Hardness (HRA) | 88 | 84 - 87 |

| Diamond Grain Size (μm) | 30 - 50 | 25 - 45 |

| Wheel Wear Rate (mg/min) | 1.2 | ~3.5 |

| Operating Load Tolerance (N/mm²) | 320 | 250 - 280 |

A leading automotive parts manufacturer in Germany deployed the Sintered Diamond Grinding 100 to optimize grinding of gray cast iron automotive brake components operating under sustained high loads. Compared to their previous grinding wheels, downtime due to tool wear decreased by 45%, and surface finish consistency improved by 30%, boosting throughput significantly.

.png)

Meanwhile, a stainless steel fabrication plant in the US reported remarkable durability using this grinding tool for high-precision hard alloy components. Tool life extensions of up to 50% minimized replacement frequency and contributed to a 20% reduction in overall production costs, even under rigorous workload fluctuations.

The multidimensional adaptability of the Sintered Diamond Grinding 100 stems from its tailored specification options. Whether tackling thermal-sensitive stainless steel that demands gentle yet effective grinding or the abrasive-hard nature of cemented carbides, the product lineup accommodates various grain sizes, bond types, and wheel diameters. This flexibility empowers manufacturers to precisely align tool characteristics with material challenges, optimizing machining cycles and extending overall service life.

Henan Youde Superhard Tools stands firmly behind its “Durability is the True Principle” philosophy, offering comprehensive technical backup and after-sales service to clients worldwide. Detailed guidelines for wheel conditioning, cooling strategies, and grinding parameter calibration empower users to maximize performance durability. Periodic maintenance recommendations such as diamond grain re-dressing and inspection intervals are furnished to safeguard consistent operational quality.

Discover firsthand how the Sintered Diamond Grinding 100 can elevate your grinding operations when confronted with demanding high-load conditions. With proven client success stories, unparalleled wear resistance, and multi-material versatility, it’s time to choose a grinding tool that delivers not only power but also unwavering reliability.