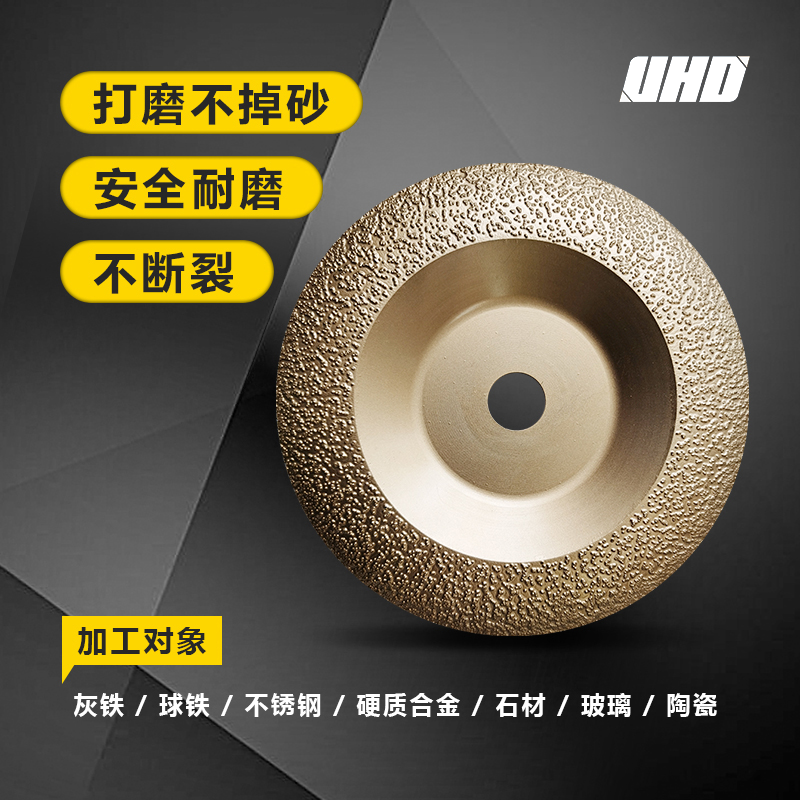

In the demanding realm of precision machining, tool durability directly impacts production efficiency and cost-effectiveness. Brazed diamond grinding tools are emerging as a benchmark for high-performance and extended lifespan in grinding applications. This article dissects the core design innovations and application successes underpinning the exceptional durability of Brazed Diamond Grinding Tools 100, showcasing their versatility on materials including gray cast iron, ductile iron, stainless steel, and cemented carbides.

The Brazed Diamond Grinding Tool 100 incorporates a meticulously engineered bonding process, where synthetic diamond grit is precisely affixed onto a metallic substrate through advanced brazing techniques. This structure ensures a seamless metallurgical bond, maximizing grit retention and minimizing abrasive loss during high-intensity usage. Compared to electroplated or resin-bonded counterparts, the brazed connection delivers superior thermal conductivity and wear resistance, which significantly reduces degradation under elevated grinding temperatures.

| Feature | Technical Benefit |

|---|---|

| Brazed Synthetic Diamond Grit | Higher grit retention, reduced wear |

| Metallic Substrate with High Thermal Conductivity | Efficient heat dissipation, prolonging tool life |

| Optimized Grain Size Distribution | Enhanced surface finish and grinding efficiency |

| Precision Brazing Process Control | Consistent product quality and predictable performance |

The brazed diamond grinding tools 100 have demonstrated notable efficacy when machining various challenging substrates:

These attributes translate to lower downtime, fewer tool changes, and enhanced surface integrity in complex machining processes.

A leading aerospace components manufacturer sought to improve the durability and reproducibility of precision grinding tools used on high-strength stainless steel alloys. Implementation of brazed diamond grinding tools 100 resulted in:

User feedback highlighted remarkable cost savings from reduced tooling replacement and less machine downtime, reinforcing the tool’s reputation for excellent return on investment.

.png)

The extended durability of brazed diamond grinding tools 100 significantly boosts production throughput. For example, a comparative analysis shows a 25% increase in grinding volume before tool replacement is required, effectively lowering the cost per part produced by up to 18%. Additionally, the reduction in tool consumption contributes to less frequent inventory cycles and green manufacturing initiatives.

| Metric | Standard Tools | Brazed Diamond Grinding Tool 100 |

|---|---|---|

| Grinding Volume Before Replacement (parts) | 1000 | 1250 (+25%) |

| Tool Life (hours) | 40 | 56 (+40%) |

| Cost per part ($) | 1.00 | 0.82 (-18%) |

.png)

With advances in brazing technology and diamond material science, brazed diamond grinding tools will continue expanding their capabilities, especially in ultra-precision fields such as aerospace, automotive, and medical device manufacturing. Their inherent high-performance profile combined with cost efficiency positions these tools as indispensable assets for enterprises aspiring to lead in competitive, innovation-driven markets.

Discover how brazed diamond grinding tools 100 can elevate your machining operations — Explore High-Durability Grinding Solutions Now