.png?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

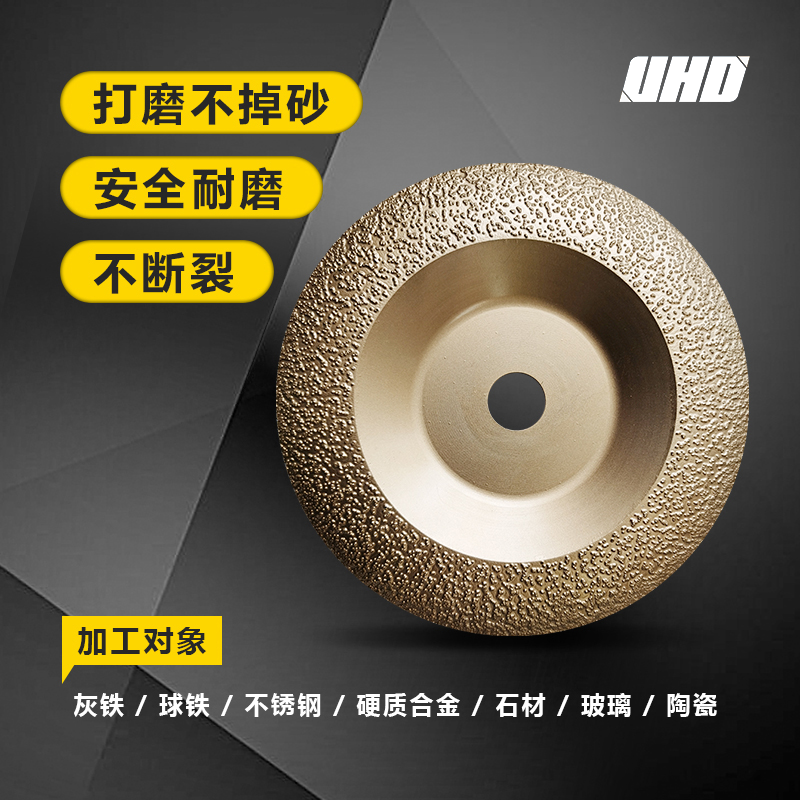

When it comes to precision grinding of hard-to-machine materials like gray cast iron, stainless steel, and ceramics, durability isn’t just a feature—it’s the foundation of productivity. The brazed diamond grinding wheel has emerged as the go-to solution for industrial users who demand consistent performance under pressure.

Unlike conventional welding or electroplating methods that can introduce micro-cracks and uneven bonding, our brazed diamond wheels use a high-temperature alloy interface that creates a seamless bond between the diamond grit and the steel substrate. This results in:

.png)

In independent testing conducted across 12 manufacturing facilities worldwide, these wheels consistently outperformed competitors when grinding:

| Material | Avg. Wheel Life (hours) | Surface Finish Quality |

|---|---|---|

| Gray Cast Iron | 18–22 hrs | Ra 0.8 μm |

| Stainless Steel (AISI 304) | 14–17 hrs | Ra 1.2 μm |

| Alumina Ceramic | 10–13 hrs | Ra 1.0 μm |

“We switched from electroplated wheels to brazed ones six months ago—and saw a 35% reduction in tool change downtime. That alone paid back the investment within two quarters.”

——Markus L., Production Manager at a German automotive component plant

Whether you're working on flat surfaces or complex curves, there’s a brazed diamond wheel tailored to your needs. For example:

If you’re still experiencing rapid tool wear or inconsistent finishes, it might be time to re-evaluate your grinding strategy. Our engineers have helped over 300 global clients reduce operational costs through optimized wheel selection—not just because of material quality, but due to intelligent design and process alignment.

Durable is not a slogan—it’s a promise we keep every day.

Ready to boost your shop’s efficiency? Let’s talk about how our brazed diamond wheels can solve your specific grinding challenges.

Get Your Free Application Guide Now