Brazed diamond abrasives represent a significant innovation in the field of mechanical processing. Their design concept is centered around maximizing the performance of diamond particles. The manufacturing technology involves a precise brazing process that firmly bonds diamond to the substrate. This not only ensures the stability of the diamond particles during high - speed operation but also enables the efficient transfer of cutting forces, which is crucial for high - precision machining.

One of the most prominent features of brazed diamond abrasives is their excellent wear resistance. Tests have shown that compared with traditional abrasives, the wear rate of brazed diamond abrasives is reduced by up to 60%. This means that they can maintain a sharp cutting edge for a longer time, significantly reducing the frequency of tool replacement and improving production efficiency.

In high - impact machining operations, the anti - stamping performance of abrasives is critical. Brazed diamond abrasives have a unique structure that can effectively absorb and disperse impact forces. Research indicates that they can withstand impact forces up to 50% higher than ordinary abrasives, ensuring stable operation in harsh working environments.

Safety is always a top priority in mechanical processing. Brazed diamond abrasives are designed with safety in mind. The firm bonding between the diamond and the substrate reduces the risk of diamond particles flying off during operation, protecting operators from potential hazards. Moreover, their stable performance also reduces the probability of machine failures, further enhancing workplace safety.

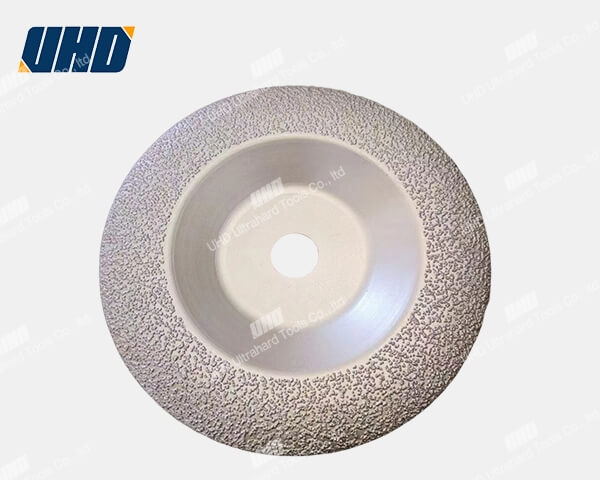

To meet the diverse needs of different machining operations, brazed diamond abrasives come in a wide range of sizes and shapes. Whether it is a small - scale precision machining or a large - scale roughing operation, there is a suitable abrasive available. For example, the bowl - shaped diamond abrasive discs are particularly suitable for grinding large - area surfaces, while smaller disc - shaped abrasives are ideal for detailed processing.

An overseas mechanical processing factory was facing challenges in meeting high - volume production requirements due to low machining efficiency. After adopting the bowl - shaped cast - iron brazed diamond abrasives, the situation changed dramatically. In the first three months of use, the factory's production efficiency increased by 40%. The specific data shows that the time required for processing a single workpiece was reduced from an average of 10 minutes to 6 minutes.

The key to this improvement lies in the excellent performance of the brazed diamond abrasives. Their high wear resistance and anti - stamping performance allowed for continuous high - speed machining without frequent tool changes. The diverse sizes and shapes also enabled the factory to optimize the machining process for different workpieces, further improving efficiency.

Users of brazed diamond abrasives have provided positive feedback. Many operators have noted that the abrasives are easy to use and can achieve high - quality machining results. They also appreciate the safety features of the product, which have reduced the risk of workplace accidents. In addition, the long service life of the abrasives has significantly reduced the overall cost of machining for enterprises.

In the highly competitive market of abrasives, brazed diamond abrasives stand out with their innovation and durability. Their ability to improve machining efficiency and safety, combined with the ability to meet diverse machining needs, gives them a strong competitive edge. For enterprises in the mechanical processing industry, choosing brazed diamond abrasives means achieving higher productivity, lower costs, and better product quality.

Discover how our innovative brazed diamond abrasives can transform your machining operations. Click here to learn more.