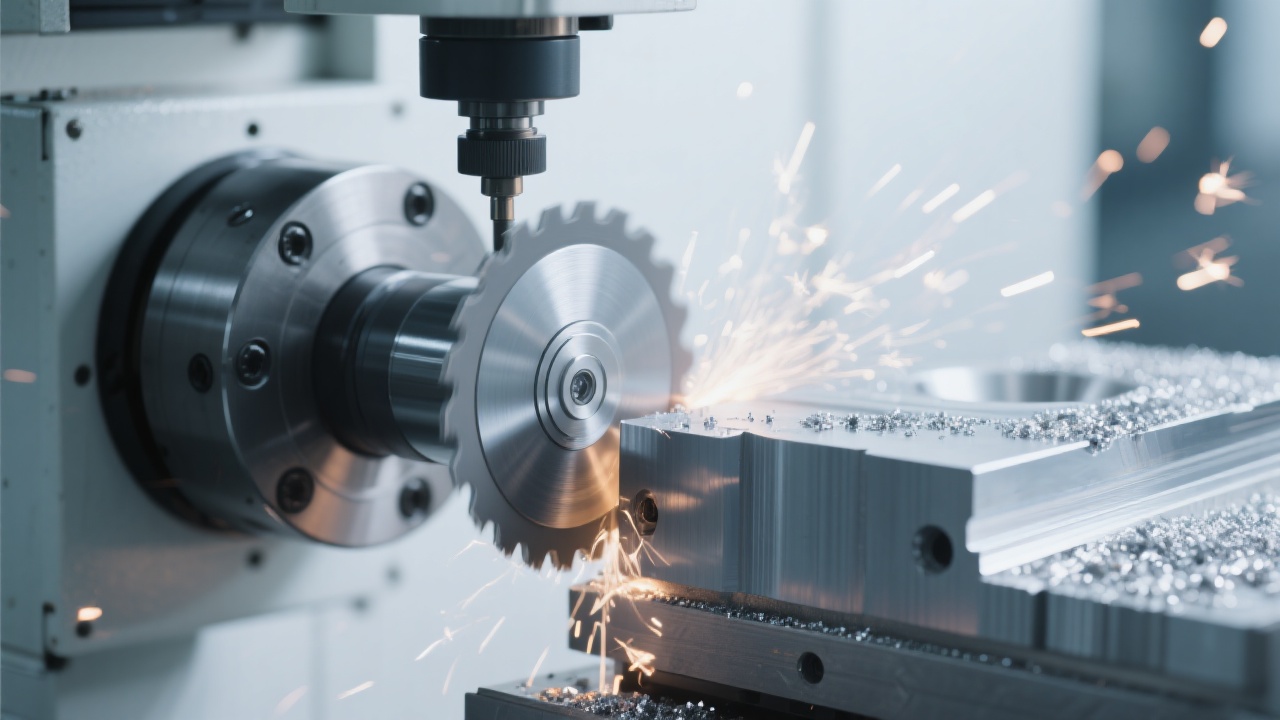

In the era of industrial green revolution, integrating environmental stewardship into manufacturing processes has become imperative. As industries worldwide strive to reduce carbon footprints and enhance resource efficiency, technologies such as diamond grinding wheels are gaining traction for their superior performance in ductile iron machining and their substantial contribution to energy saving and pollution reduction.

Diamond grinding wheels are engineered with synthetic diamond abrasive grains bonded to a metal or resin matrix, offering high hardness and thermal conductivity unmatched by conventional abrasives. This composition allows for precise, efficient material removal with reduced wear. The intrinsic properties enable:

The material science behind diamond wheels is critical in supporting green manufacturing goals, particularly when applied in abrasive tasks such as ductile iron component production.

| Aspect | Diamond Grinding Wheel | Conventional Wheel |

|---|---|---|

| Dust Emission Reduction | Up to 40% lower particulate matter | Baseline |

| Material Utilization Efficiency | Above 90% | Around 75% |

| Energy Consumption per Unit | ~20% less | Baseline |

The reduced dust emission is particularly significant in controlling workplace health hazards. Studies in foundry environments demonstrate that implementing diamond grinding wheels can decrease particulate matter by up to 40%, contributing to safer factory conditions and complying more readily with environmental regulations.

Leading manufacturers in the automotive and industrial sectors have reported remarkable gains using diamond grinding wheels. For example, a major automotive parts producer reduced abrasive consumption by 35% and cut energy costs by 15% after switching to diamond wheels for ductile iron brake rotor machining. Another foundry noted a 28% improvement in surface finish consistency, which decreased rework rates and scrap generation.

“The transition to diamond grinding technology has been transformative—not just for operational efficiency, but also for our sustainability commitments. It’s a clear win for green manufacturing.” – Quality Manager, Leading Foundry, Germany

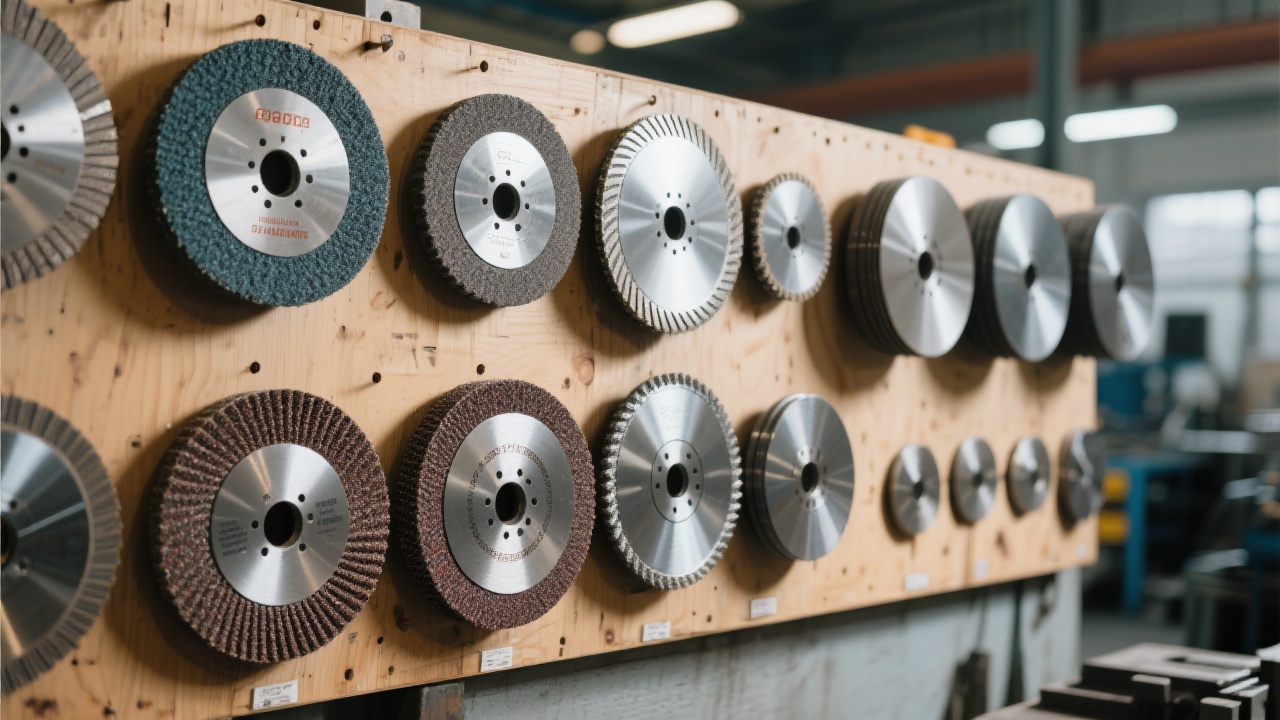

To maximize environmental benefits, manufacturers should adopt best practices in diamond wheel use:

A well-maintained diamond grinding wheel not only sustains operational excellence but further reduces environmental impact through extended service life and stable performance.

Explore how adopting advanced diamond grinding wheels can accelerate your green manufacturing journey — Discover cutting-edge technology for sustainable industrial machining