Brazed diamond grinding wheels, particularly the bowl-type varieties, represent a pinnacle in abrasive technology for machining hard materials. Their innovative design principles and state-of-the-art manufacturing processes cater to the rigorous demands of processing tough substrates such as gray cast iron, ductile iron, and stainless steel. This article offers a comprehensive examination of these grinding wheels, emphasizing how their structural and material innovations translate into significant efficiency gains and extended service life.

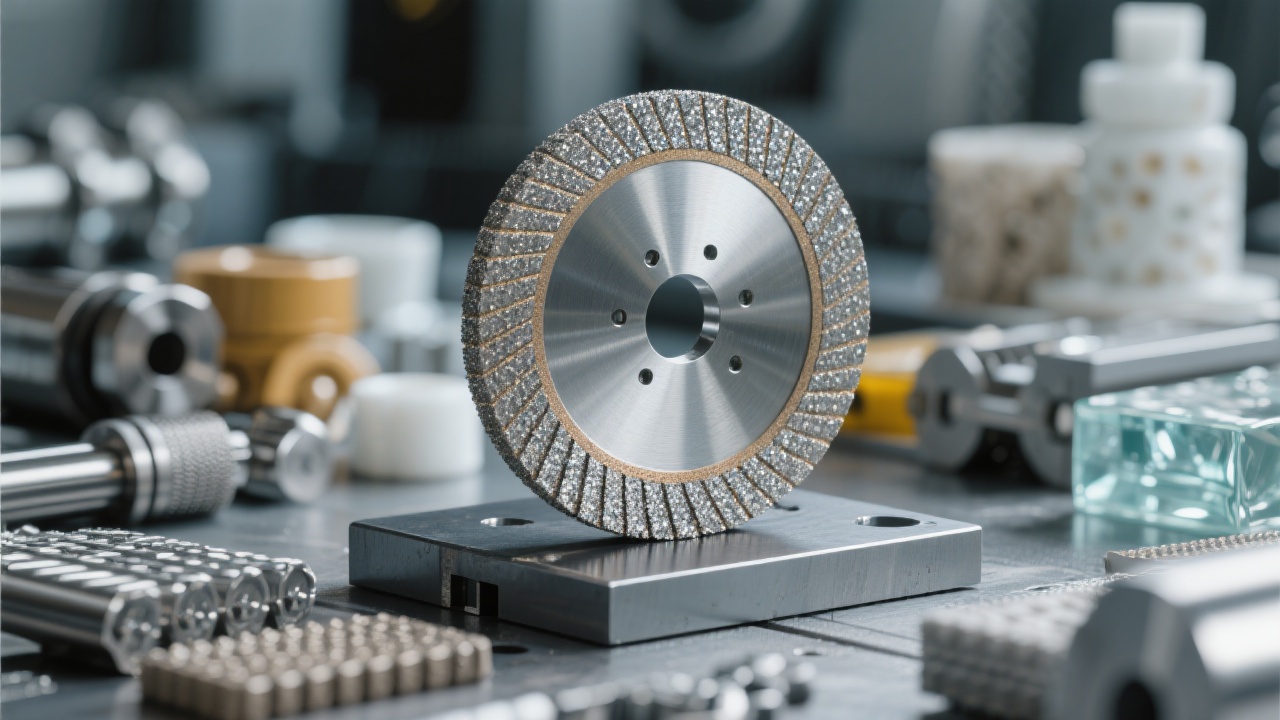

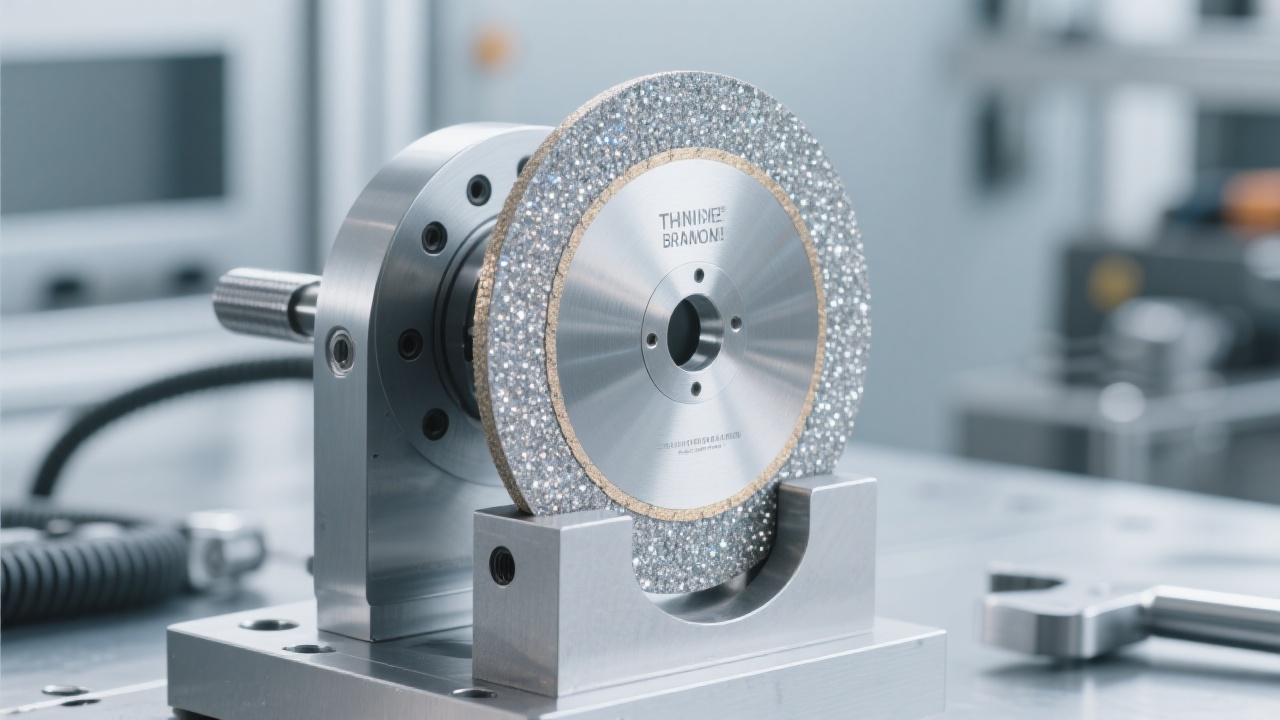

The core strength of brazed diamond grinding wheels lies in their meticulous structural design. The bowl shape not only facilitates optimal chip removal but also improves contact consistency between abrasive and workpiece, ultimately enhancing surface finish and removal rates. Selecting premium-grade synthetic diamond abrasives, in conjunction with high-temperature brazing alloys, ensures maximal bonding strength and thermal stability.

Material choice impacts wear resistance as well. The brazing process bonds diamond grains to a metallic matrix, preventing premature diamond loss that often causes performance degradation in resin-based or electroplated wheels. The optimized grain size distribution facilitates progressive wear, maintaining sharp cutting edges throughout the wheel’s lifespan.

These grinding wheels demonstrate pronounced advantages when applied to high-hardness materials. In gray iron and ductile iron casting machining, their sharpness and controlled wear reduce grinding forces by an estimated 15-20%, allowing accelerated removal rates without compromising dimensional accuracy or surface integrity.

When applied to stainless steel machining, concerns about wheel clogging are effectively mitigated due to the braze’s hardness and diamond exposure geometry. The durability and thermal conductivity of brazed wheels reduce heat generation, limiting thermal damage and expanding tool longevity significantly over resin- or vitrified-bond alternatives.

Safety remains paramount in high-speed abrasive tooling. The brazed diamond wheels’ robust bond ensures that diamond particles remain securely anchored, eliminating risks of chipping or fragment release during high-speed rotation. Their structural integrity complies with, and often exceeds, ISO and ANSI safety standards for grinding wheels, delivering peace of mind alongside high performance.

Field data indicates these wheels maintain over 85% of their initial grinding efficiency after 100+ operational hours, outperforming competitive wheels by approximately 30%, significantly reducing downtime and tooling costs.

To adapt to diverse industrial requirements, brazed diamond grinding wheels are manufactured in varying diameters, thicknesses, and grain configurations. Whether for intricate mold polishing or heavy-duty cast iron grinding, selecting the correct wheel form factor is crucial. Detailed specifications, including the grit size, bonding alloy composition, and geometric profiling, are customizable to optimize cutting rates and finish quality per application.

The ability to supply wheels compliant with international standards enables global users across automotive, aerospace, and heavy machinery sectors to leverage these cutting-edge abrasives confidently.

Numerous case studies validate the performance claims of brazed diamond grinding wheels. Notably, a leading automotive component manufacturer reported a 30% increase in production throughput after integrating these wheels into their finishing line, while noting a substantial reduction in wheel changeovers owing to improved wear resistance.

User testimonials frequently highlight the consistent grinding quality and minimal operator fatigue due to reduced vibration and optimized cutting forces.