In today’s high-stakes manufacturing environment, consistency, precision, and uptime aren’t just goals—they’re non-negotiables. That’s where brazed diamond grinding tools come in: not as a luxury, but as a necessity for industries pushing the limits of material science.

Traditional grinding wheels often fail under demanding conditions—especially when working with materials like stainless steel, gray cast iron, or advanced ceramics. Studies show that conventional tools lose up to 40% of their cutting efficiency within 20 hours of continuous use. In contrast, modern brazed diamond tools from companies like Henan Youde Superhard Tools Co., Ltd. deliver over 70% longer life and consistent surface finish across batches—a game-changer for automated production lines.

Manufacturers face three major challenges:

Brazing technology addresses all three by fusing diamonds directly into a high-strength alloy matrix using controlled heat and pressure. This creates a bond far superior to mechanical bonding or electroplating—resulting in a tool that maintains sharpness for thousands of parts without reconditioning.

“We tested the new 100mm brazed diamond grinding disc on hardened stainless steel components. After 120 hours of continuous operation, it still achieved Ra 0.4 μm surface finish—no drop-off.”

— Dr. Li Wei, R&D Manager at a Tier-1 automotive supplier in Germany

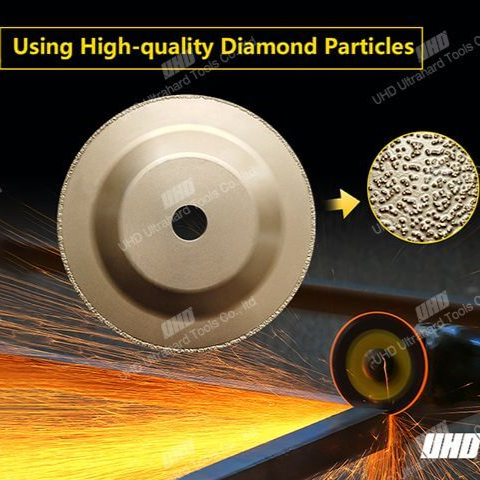

The latest model from Youde features a precision-engineered tungsten carbide base combined with proprietary brazing alloy. The result? A 3x increase in impact resistance compared to standard diamond wheels—and a 50% reduction in tool replacement frequency in real-world applications.

Whether you're machining ceramic substrates for semiconductors or finishing turbine blades made of Inconel, this solution is engineered for extreme durability—not just incremental improvement.

As automation grows, so does demand for modular grinding solutions tailored to specific processes. Buyers now expect tools that integrate seamlessly with CNC systems, offer real-time wear monitoring, and can be easily swapped out during maintenance windows. Youde’s 100mm disc already supports quick-change mounting options—an early win in the race toward Industry 4.0-ready tooling.

Discover how our 100mm brazed diamond grinding disc delivers unmatched durability and precision for your toughest materials.

Get the Technical Brochure & Start Testing