1) Choose grit size by goal, not habit

For stock removal on carbide, 80/100 to 100/120 grit is common. For finishing, 150/180 to 200/230 can reduce Ra while keeping cutting action. Too fine too early often increases rubbing and heat.

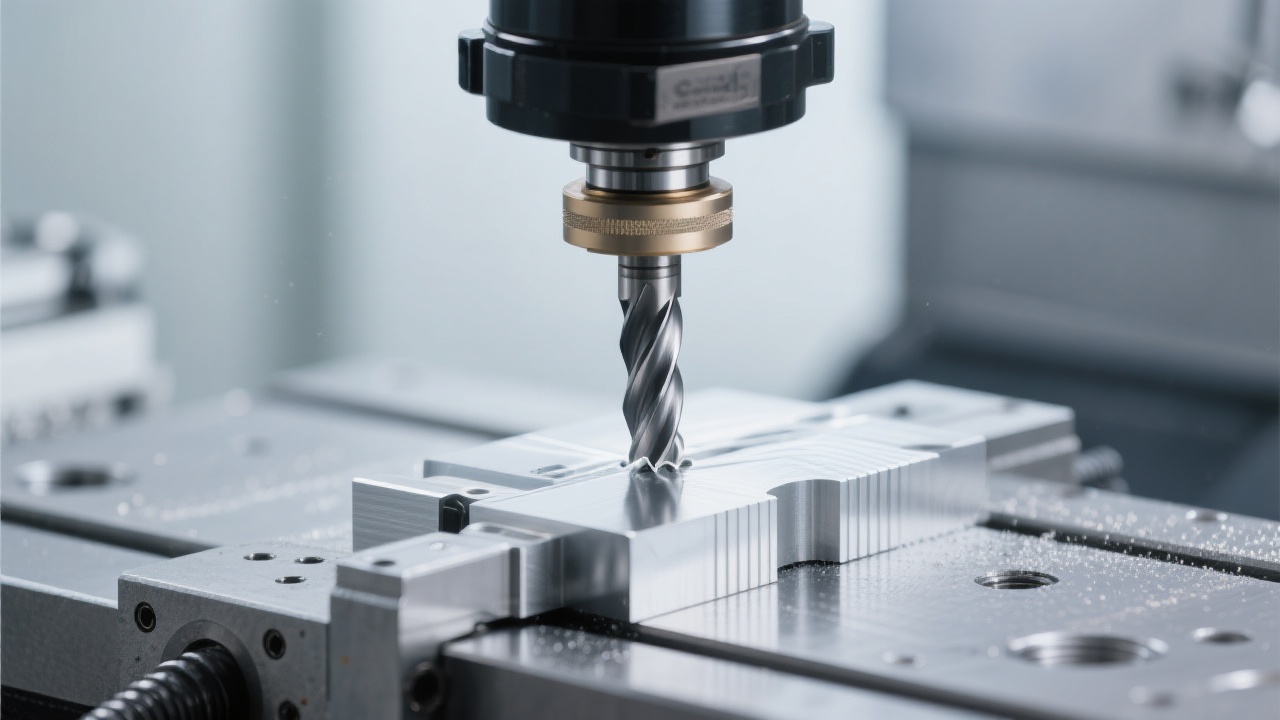

In tungsten carbide grinding, “good enough” often turns into rework, overheating, and accelerated wheel wear. Brazed diamond grinding tools have become a practical answer for shops that need stable geometry, predictable tool life, and cleaner surfaces on hard alloys and other high-strength materials. The following case study style analysis focuses on what actually changes on the shop floor—material removal rate, downtime, and surface integrity—when brazed diamond is applied correctly.

Brazed diamond grinding tools differ from conventional resin-bond and metal-bond wheels in one key way: the diamond grit is metallurgically brazed to the substrate, creating strong grit retention and a more open cutting structure. In tungsten carbide and hard alloys, that combination can reduce rubbing and heat buildup—two of the most common triggers for micro-chipping, cobalt binder smearing, and premature wheel glazing.

Practical outcomes often reported by industrial users include faster stock removal, fewer dressing interruptions, and more stable edge definition on complex carbide profiles. While exact results depend on grit size, tool geometry, coolant, and machine rigidity, the mechanism is consistent: sharper cutting action + stronger grit holding translates into more cutting and less friction.

Reference ranges are compiled from common shop reports for carbide grinding under adequate coolant and stable spindle conditions; results vary by grade, setup rigidity, and grit specification.

In industrial grinding, the best tool is the one that stays stable when conditions get difficult: interrupted cuts, variable contact area, and hard-to-cool geometries. Brazed diamond tools are commonly selected for: tungsten carbide (WC-Co), hard alloys, cermets, technical ceramics, and composites. For non-ferrous hard materials such as glass and stone, brazed diamond can also deliver aggressive cutting with manageable heat.

They are generally not the first choice for ferrous materials where diamond can suffer from chemical wear at high temperature; when steel is involved, CBN often becomes the more appropriate abrasive. For carbide, however, brazed diamond is a direct productivity lever.

A tooling manufacturer grinding tungsten carbide punches for progressive dies faced two recurring issues: thermal discoloration at the edge radius and frequent wheel touch-ups to restore sharpness. The shop shifted to a brazed diamond profile tool matched to the punch contour and adjusted process parameters to emphasize cooler cutting.

“The biggest change was stability. The profile stayed sharp longer, and we stopped chasing burn marks at the radius. Output improved without adding machines.” — Production Supervisor, Precision Tooling Plant (East Asia)

The difference between a “good tool” and a measurable production upgrade is usually process discipline. In carbide grinding with brazed diamond, the most repeatable wins come from controlling heat, chip evacuation, and contact mechanics.

For stock removal on carbide, 80/100 to 100/120 grit is common. For finishing, 150/180 to 200/230 can reduce Ra while keeping cutting action. Too fine too early often increases rubbing and heat.

Carbide punishes dry zones. A practical target is 20–40 L/min for typical surface/profile grinding setups, with nozzle alignment focused directly at the contact arc to prevent local hot spots.

Dwell is where thermal damage sneaks in—especially on small radii. Favor continuous motion and controlled infeed. If geometry requires a pause, reduce pressure and improve coolant coverage first.

Overloading raises temperature and can shorten tool life. A shop-friendly indicator is spindle load stability: aim for a steady load band rather than peaks. When the tool is correctly specified, it should feel “free cutting.”

A pump component supplier was grinding carbide seal rings and struggling with unplanned interruptions: glazing, repeated dressing, and quality checks that slowed shipments. After switching to a brazed diamond wheel/tooling solution and standardizing a two-step rough/finish approach, the line moved from “interrupt-driven” to schedule-driven.

“Once the process was standardized, the tool behavior became predictable. Our operators stopped ‘nursing’ the grind and started running the plan.” — Quality & Process Engineer, Industrial Pump Components (EU)

For procurement and engineering teams, the fastest path to a successful trial is aligning tool specification with the real constraint: removal rate, surface finish, or profile accuracy. In most carbide projects, selection can be simplified into a few decision points:

The trend in advanced grinding is moving toward application validation: buyers increasingly request proof of stability on their carbide grade, not just a catalog specification. Leading suppliers are responding with faster prototyping, more consistent brazing quality control, and data-backed parameter recommendations to shorten qualification cycles.

Henan Youde Superhard Tools Co., Ltd. continues to expand its industrial grinding portfolio around brazed diamond solutions for tungsten carbide and other high-strength materials, focusing on repeatable cutting performance, customization capability, and production-level consistency that engineers can defend in audits and PPAP-style documentation.

Share your carbide grade, drawing, and current process target (MRR, Ra, or profile tolerance). A correctly matched brazed diamond grinding tool can often reduce dressing interruptions, stabilize edge quality, and increase output in the same footprint.

Request a Brazed Diamond Grinding Tool Recommendation for Tungsten CarbideTypical response time: 24 hours (business days). Parameter guidance can be provided for trial runs.