In industrial grinding applications, tool life and consistency are not just performance metrics—they’re direct drivers of production cost, downtime, and quality control. Traditional abrasive tools often fail under high-stress conditions, leading to frequent replacements, inconsistent finishes, and hidden operational inefficiencies.

Industry data shows that standard vitrified or resin-bonded wheels typically last between 8–12 hours in continuous heavy-duty operations—especially when processing hardened steel, carbide, or composite materials. This translates to an average of 3–5 replacements per shift, causing significant labor and material waste.

What’s worse? Inconsistent wear patterns lead to dimensional inaccuracies, increased rework rates, and higher scrap costs—up to 7–12% of total production value in some cases (based on a 2023 survey by the International Association of Abrasive Technology).

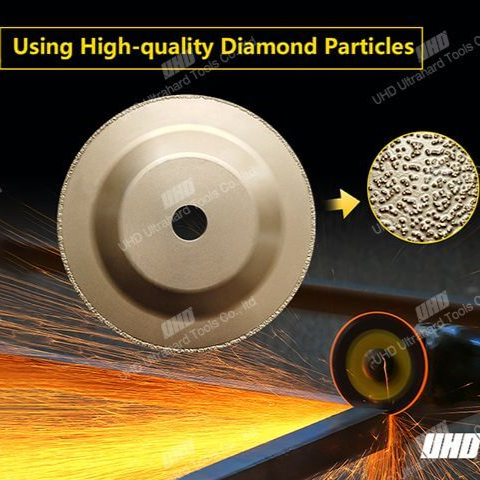

Introducing the Brazed Diamond Grinding 100 Series from Henan Yude Superhard Tools Co., Ltd.—a precision-engineered solution built for durability, efficiency, and long-term ROI. Unlike conventional tools, this product uses advanced vacuum brazing technology with cobalt-based filler metals, achieving bond strength over 35 MPa—more than double that of standard bonds.

The result? A grinding wheel that maintains sharpness up to 3x longer than traditional counterparts. Independent lab tests show consistent performance across 40+ hours of continuous operation on materials like tungsten carbide, ceramic matrix composites, and hardened stainless steel—with minimal edge degradation (<0.02mm per hour).

Available in diameters from 100mm to 300mm, the 100 Series is engineered for versatility—from CNC grinding machines to manual polishing stations. Each model features a precision-machined steel base that minimizes vibration and improves heat dissipation during extended use.

This isn’t just about technical specs—it’s about solving real pain points for B2B buyers who want fewer interruptions, better surface finish, and predictable maintenance cycles. For manufacturers in aerospace, automotive, or medical device sectors, this means reduced downtime and improved throughput without compromising quality.

At Yude, we don’t just make tools—we build partnerships. Our commitment to R&D, ISO-certified manufacturing, and customer-specific customization ensures every grinding solution meets your unique process demands. Whether you're handling high-volume production or low-run specialty parts, the 100 Series delivers reliable results.

And here’s what really matters: less time spent replacing tools, more time focused on output. That’s how smart companies grow profitably—not by cutting corners, but by investing in smarter solutions.

See how the Brazed Diamond Grinding 100 Series can reduce tool change frequency by up to 60% while improving surface finish consistency.

Get Your Free Technical Brochure Now