Every manufacturing facility faces the same silent productivity killer: frequent tool changes. When a grinding wheel wears out prematurely, it doesn't just cost money for replacements—it disrupts workflows, increases labor costs, and creates bottlenecks in production schedules. For shops working with hardened steel, cast iron, or stone materials, this problem becomes even more pronounced. But what if there was a grinding solution that could double, or even triple, your tool life while maintaining consistent performance?

"We were changing conventional grinding wheels every 2-3 hours when working with ductile iron castings. After switching to brazed diamond technology, we're getting 8-10 hours of continuous use. The difference in productivity is night and day." — Mark Thompson, Production Manager at Precision Castings Inc.

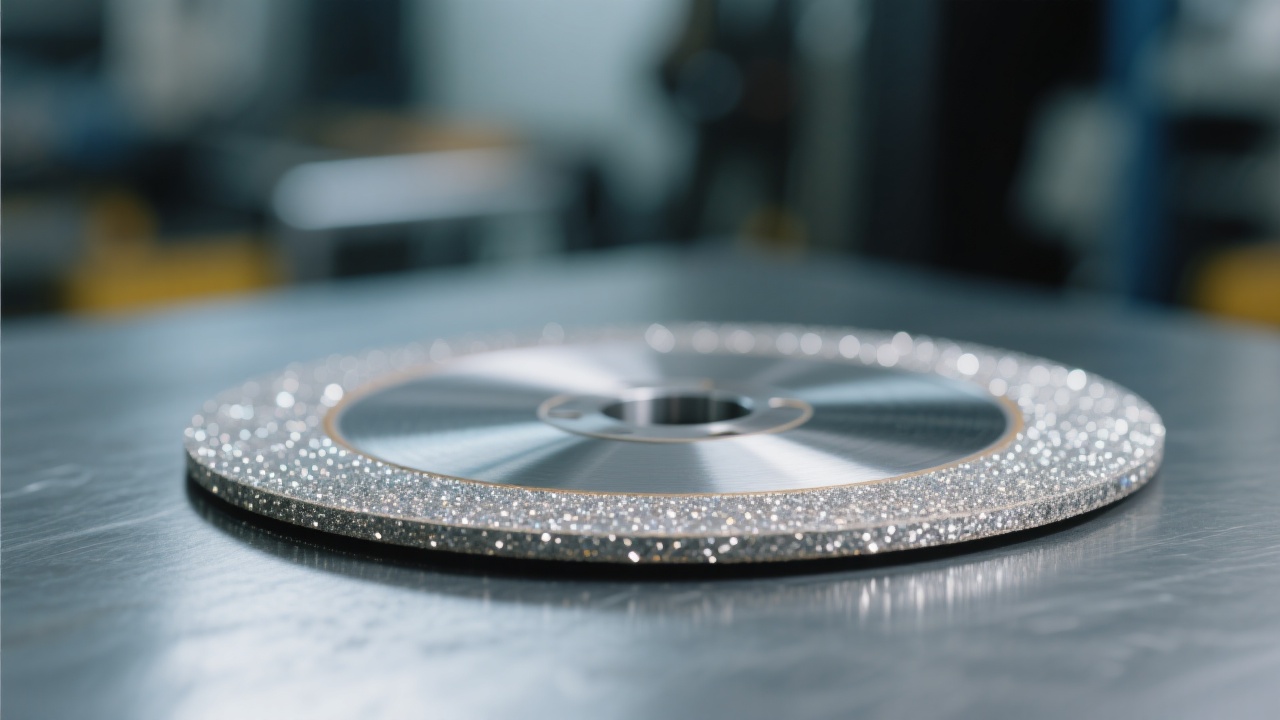

The fundamental difference between brazed diamond磨片 and traditional grinding tools lies in how the diamond particles are secured to the substrate. Conventional methods use either resin bonding or electroplating, which typically encapsulate only a portion of each diamond particle. This limited adhesion means diamonds can dislodge prematurely, drastically reducing tool life.

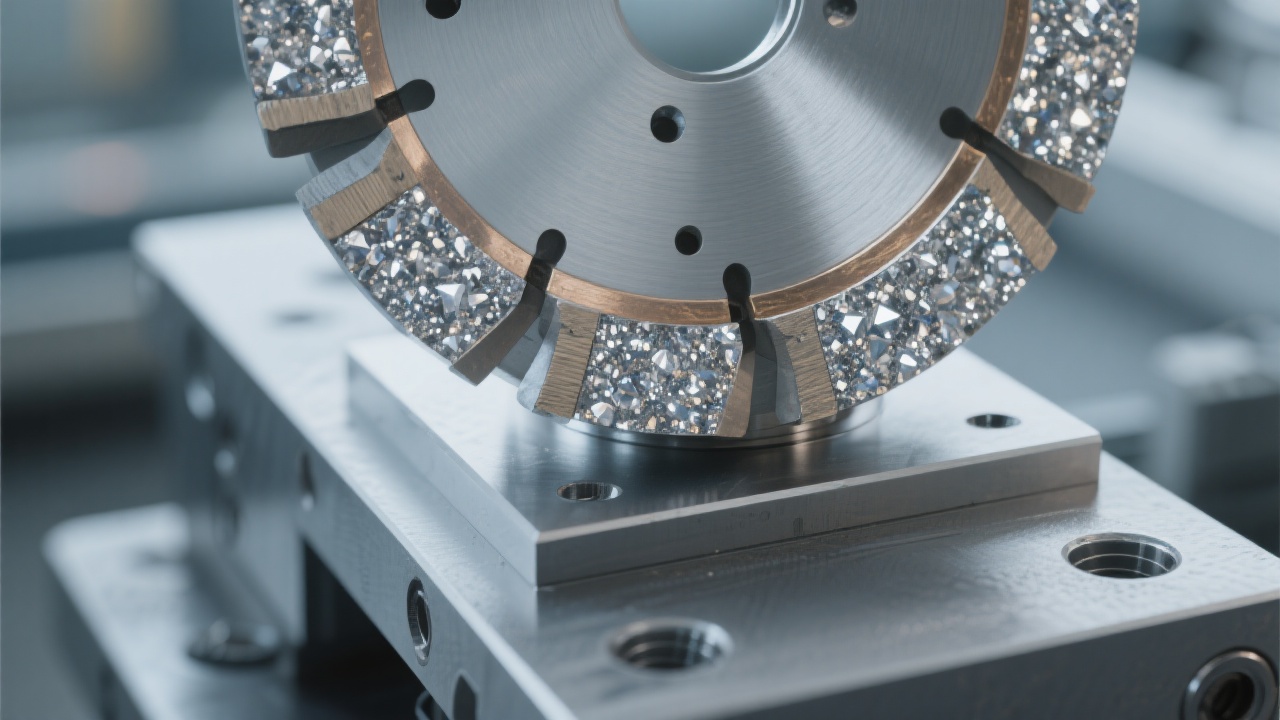

Brazing technology changes this equation completely. Through a precise high-temperature process (typically 850-1050°C), a specialized alloy forms a metallurgical bond directly with the diamond surface and the tool substrate. This creates a mechanical lock that securely holds each diamond particle while exposing up to 70% of the diamond surface—significantly more than the 20-30% exposure in conventional tools. The result? A grinding wheel that maintains its cutting efficiency longer and resists premature wear.

Crafting a high-performance brazed diamond磨片 involves a symphony of precision engineering and material science. The process begins with diamond selection—only premium grade synthetic diamonds with controlled crystal structure and toughness are chosen. These diamonds are then meticulously arranged in specific patterns using computer-aided design, ensuring optimal spacing and distribution for consistent grinding action.

Laboratory testing and field trials consistently demonstrate the superiority of brazed diamond technology across various materials. In controlled tests comparing brazed diamond磨片 with conventional resin-bonded wheels:

| Material | Tool Life (Brazed) | Tool Life (Conventional) | Efficiency Increase |

|---|---|---|---|

| Gray Cast Iron | 12.5 hours | 3.8 hours | 229% |

| Stainless Steel (304) | 9.2 hours | 2.5 hours | 268% |

| Granite (Polished) | 18.7 hours | 5.2 hours | 259% |

These performance gains translate directly to the bottom line. A mid-sized machine shop processing 500 cast iron parts weekly reported saving over $12,000 annually after switching to brazed diamond磨片, considering both material costs and reduced downtime.

Different manufacturing sectors face unique grinding challenges, and brazed diamond磨片 offers tailored solutions across industries:

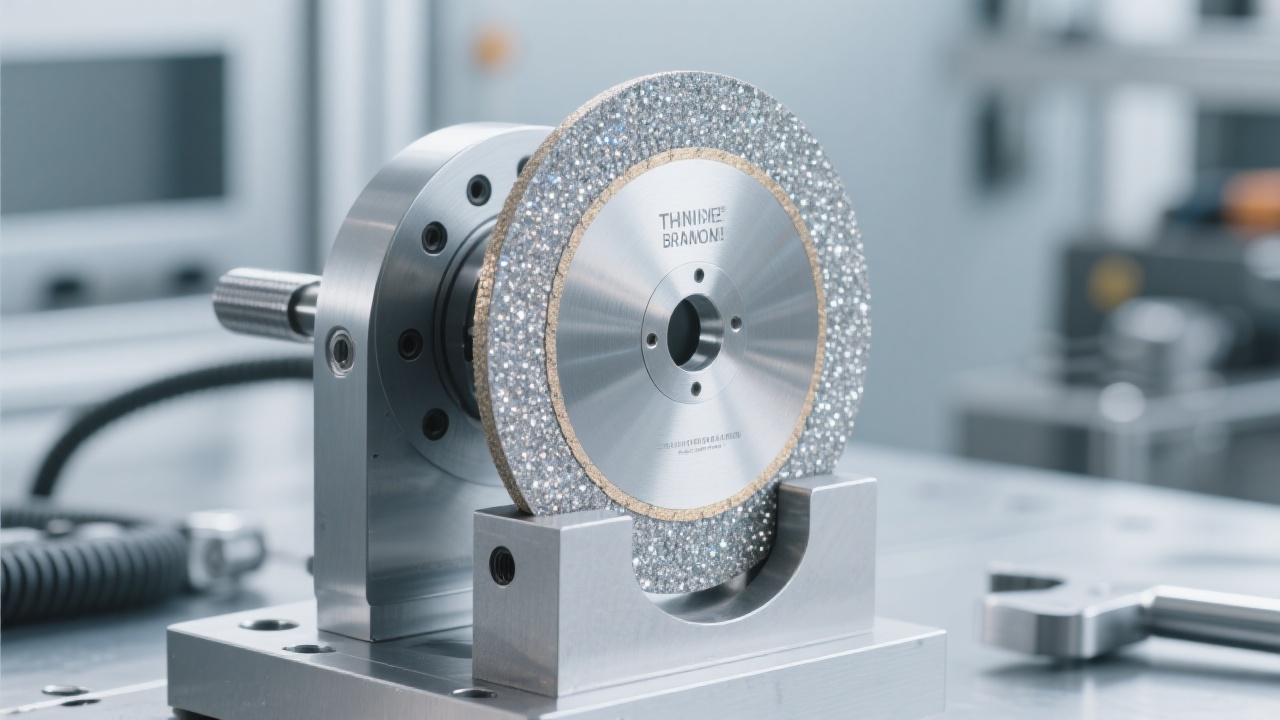

For cylinder head and engine block grinding, the consistent performance of brazed diamond磨片 maintains tight tolerances (±0.002mm) throughout the tool life, reducing the need for frequent recalibration.

When cleaning castings with varying surface hardness, the self-sharpening nature of brazed diamonds ensures consistent material removal rates without loading or glazing.

The enhanced diamond exposure provides faster stock removal while maintaining surface finish quality, reducing the need for secondary polishing operations.

If you're experiencing any of these common issues, brazed diamond technology could transform your operations:

While brazed diamond磨片 may represent a higher initial investment compared to conventional grinding wheels, the total cost of ownership tells a different story. Consider these factors:

Reduced labor costs from fewer tool changes, less machine downtime, and decreased inspection requirements. Improved process stability that reduces scrap rates and rework. Energy savings from maintaining optimal cutting efficiency throughout the tool life. When these factors are combined, most manufacturers see a return on investment within 2-3 months of implementation.

Discover how our brazed diamond磨片 technology can reduce your tooling costs by up to 60% while increasing production output. Join hundreds of manufacturers who have already made the switch to longer-lasting, more efficient grinding solutions.

Request Your Free Performance AnalysisEvery manufacturing operation has unique challenges, but one truth remains constant: tool durability directly impacts your bottom line. By investing in brazed diamond technology, you're not just buying a grinding wheel—you're investing in a more efficient, reliable, and profitable manufacturing process. The question isn't whether you can afford to upgrade your grinding tools, but whether you can afford not to.