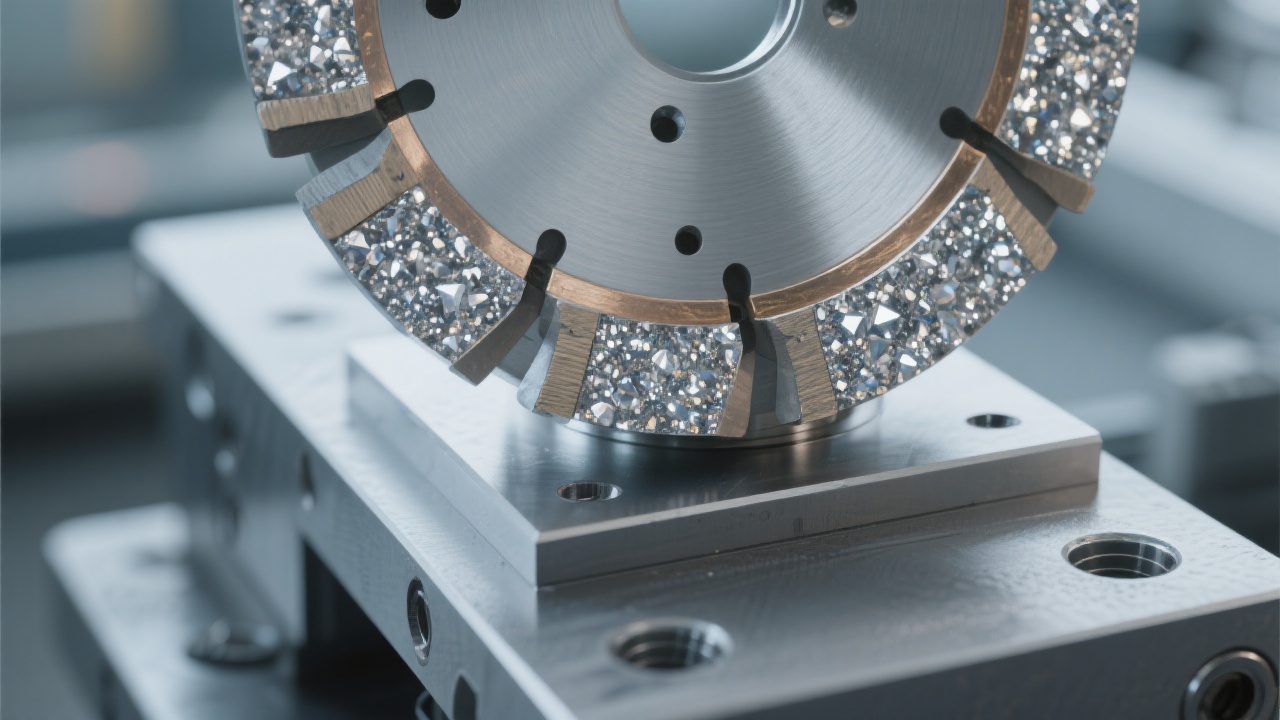

The Brazed Diamond Grinding Disc 100 stands out in the market for its exceptional high wear - resistance and efficient cutting ability. It is specifically designed to handle a wide range of hard - to - machine materials. In high - intensity industrial grinding operations, the disc's wear - resistant nature ensures that it can endure the harsh grinding process. For example, compared to traditional grinding discs, it can last up to 3 times longer in continuous grinding tasks. Its efficient cutting ability allows for a significant reduction in grinding time. Tests have shown that it can increase the grinding efficiency by up to 40% when working on difficult - to - process materials.

The brazing technology used in the Brazed Diamond Grinding Disc 100 is a key factor in enhancing its structural strength and service life. Through this advanced brazing process, the diamond particles are firmly bonded to the base, preventing them from falling off during the grinding process. This not only improves the overall structural strength of the grinding disc but also extends its service life. In practical applications, grinding discs with this brazing technology can withstand up to 50% more pressure than those without, and their service life can be extended by up to 60%.

This grinding disc has a wide range of applications. In the gray iron industry, it can quickly and accurately grind the surface of gray iron castings, improving the surface finish and dimensional accuracy. For stainless steel processing, it can effectively remove burrs and perform surface polishing, ensuring high - quality finished products. In the ceramic and stone industry, it can handle the cutting and grinding of hard ceramic and stone materials, meeting the high - precision requirements of these industries. The following table shows the typical application scenarios and their corresponding benefits:

| Application Scenario | Benefits |

|---|---|

| Gray Iron Industry | Improved surface finish and dimensional accuracy |

| Stainless Steel Processing | Effective burr removal and surface polishing |

| Ceramic and Stone Industry | High - precision cutting and grinding |

"Since we started using the Brazed Diamond Grinding Disc 100, our production efficiency has increased significantly, and the maintenance cost has been reduced by nearly 30%. It is really a reliable grinding tool." - A manufacturing enterprise in the metal processing industry

These real - world user experiences and data prove the stability and economic value of the product. The high reliability of the grinding disc ensures continuous and stable production, while the long service life and high efficiency help enterprises save costs and improve economic benefits.

We understand that different customers have different needs. Therefore, we offer customization services for the Brazed Diamond Grinding Disc 100. We can provide products with different diameters, apertures, and edge thicknesses to meet the personalized requirements of customers. Whether you need a special - sized grinding disc for a specific production line or a customized grinding disc for a unique processing task, we can provide you with a suitable solution.

Don't miss out on this durable and efficient industrial grinding solution! Let the Brazed Diamond Grinding Disc 100 be your reliable partner in the industrial grinding process. It's not only durable but also saves you time and effort, making every grinding operation trustworthy. Click here to learn more details or contact our technical support to get a customized solution!