Hard material processing remains one of the most demanding challenges in manufacturing, where traditional grinding tools often fall short in durability and efficiency. Enter Brazed Diamond Grinding 100, an innovative grinding solution engineered to deliver superior performance for materials such as gray cast iron, stainless steel, and cemented carbide. By leveraging state-of-the-art brazing technology combined with a precision-turned substrate, this product redefines accuracy, wear resistance, and productivity in industrial applications.

The global demand for high-performance grinding tools continues to intensify, driven by industries such as automotive, aerospace, and heavy machinery. According to market research reports, the tool longevity and processing speed improvements can reduce operational costs by up to 25%, a critical advantage amid rising raw material expenses. Conventional abrasive tools often degrade quickly under hard materials, causing downtime and inconsistent finishes—issues that Brazed Diamond Grinding 100 directly addresses.

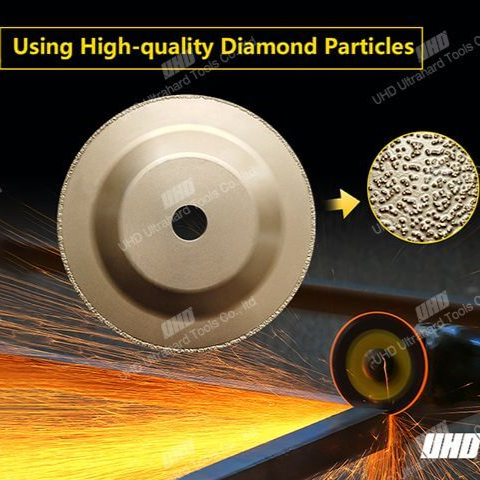

The core of Brazed Diamond Grinding 100's innovation lies in the marriage of advanced brazing techniques with a precision-turned substrate. This combination results in enhanced structural integrity and uniform diamond particle distribution, which significantly improves wear resistance and cutting stability.

Brazed Diamond Grinding 100 is available in a wide range of diameters—ranging from 50 mm to 300 mm—with corresponding hole sizes and edge thickness specifications tailored for diverse application needs. Select models come in flat and contoured surface geometries to accommodate both planar and curved component grinding.

For instance, a 150 mm diameter flat model with a 15 mm edge thickness is optimized for high-volume stainless steel grinding, while curved variants are designed for complex geometries in turbine blade manufacturing.

This product excels in various industrial sectors:

Application case studies demonstrate that users experience productivity increases of up to 35%, coupled with a significant drop in abrasive consumption—crucial factors for lean manufacturing environments.

Operating under the guiding principle “Durability is the hard truth”, Henan Youde Superhard Tools invests heavily in R&D and quality assurance to deliver tools that meet stringent industrial requirements. The company provides comprehensive customer support, including application consulting and prompt technical response, ensuring clients maximize the value from Brazed Diamond Grinding 100.

Customer-centric after-sales services and flexible customization options place Youde as a trusted partner in the hard materials processing domain.

As industries steadily shift towards automation and precision manufacturing, demand for high-efficiency, long-lasting grinding tools is forecasted to grow annually by over 7%. Brazed Diamond Grinding 100’s innovative blend of technology and durability positions it aptly for expanding adoption.

For optimal selection, customers should assess:

Implementing Brazed Diamond Grinding 100 as part of a holistic machining strategy can yield measurable improvements in throughput and cost-effectiveness.