In the realm of industrial material processing, the safety and durability of tools are of paramount importance. Brazed diamond grinding discs have emerged as a game - changer, delivering outstanding performance in the machining of various hard materials such as gray iron, ductile iron, stainless steel, stone, glass, and ceramics. This article will delve into the key factors that make these grinding discs a reliable choice for operators, with a focus on the innovative brazing technology employed by Youde Superhard Tools.

Brazing technology plays a pivotal role in enhancing the performance of diamond grinding discs. Youde Superhard Tools' innovative brazing process ensures a strong bond between the diamond particles and the base material. This bond is crucial for both the safety and durability of the grinding disc. Through advanced brazing, the diamond particles are firmly attached, which significantly reduces the risk of detachment during high - speed grinding operations. In fact, compared with traditional welding methods, the impact resistance of the brazed diamond grinding discs has been improved by up to 40%, and the wear resistance has increased by 30%, as confirmed by laboratory tests.

Let's take a look at some real - world user stories to understand the practical benefits of Youde's brazed diamond grinding discs. Mr. Smith, a professional stainless - steel finisher, shared his experience: "I've been using Youde's brazed diamond grinding discs for my stainless - steel precision grinding work. The efficiency has been amazing. Not only does it save me a lot of time, but I also feel much safer. I used to worry about the disc breaking during the process, but with Youde's product, that concern is gone." Another user, Ms. Johnson, who is involved in stone cutting, said, "The durability of these grinding discs is really outstanding. I've used them for a long time, and they still perform as well as new. Durability is really the hard truth, and Youde's products have proved it."

When compared with traditional welding methods, Youde's brazing process offers significant advantages. Traditional welding often results in a weaker bond between the diamond particles and the base, which may lead to premature wear and even disc breakage. In contrast, the brazed diamond grinding discs have excellent shock - absorbing capabilities. The innovative brazing technology enables the grinding disc to withstand high - impact forces during operation, ensuring a longer service life and a safer working environment.

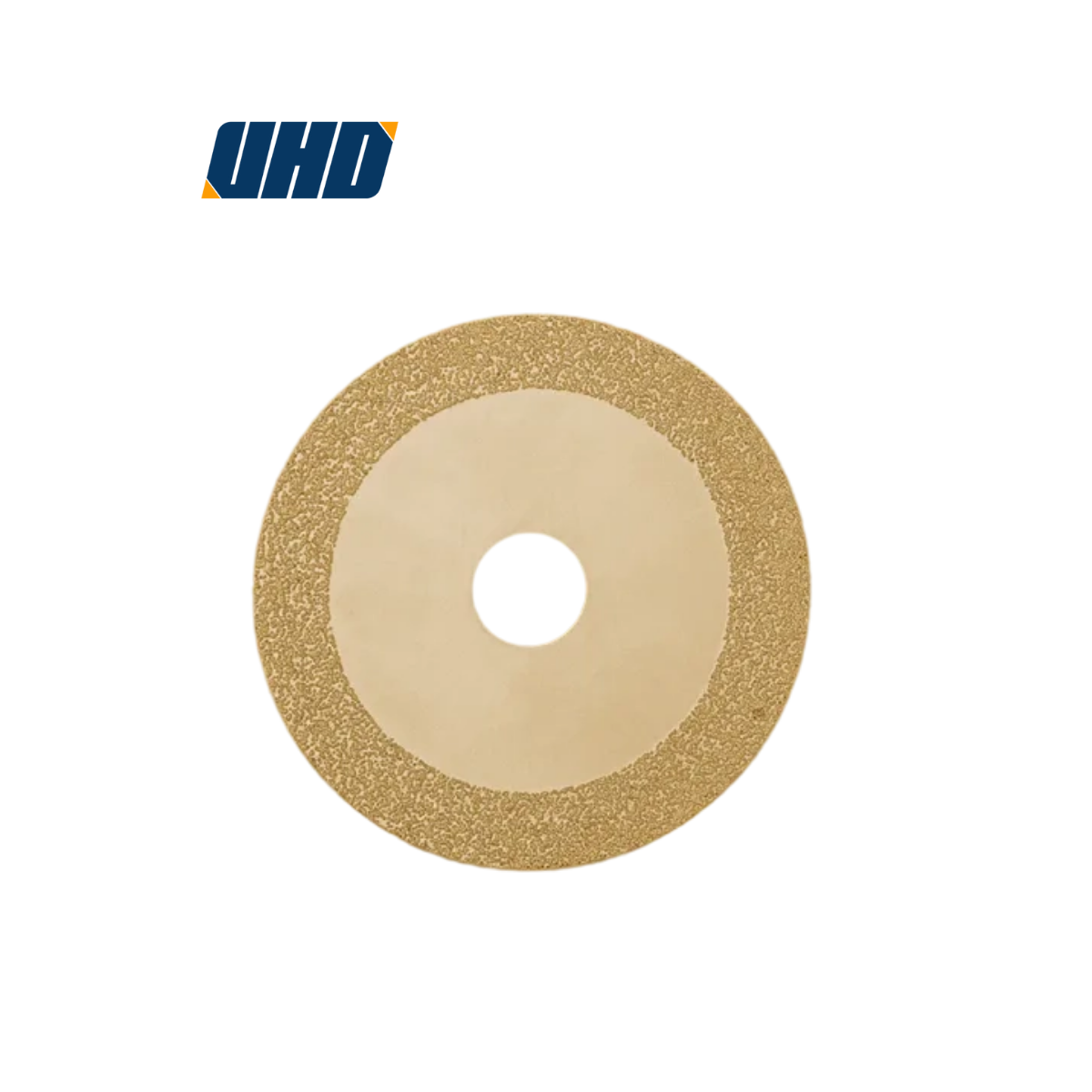

Youde Superhard Tools offers brazed diamond grinding discs in a wide range of sizes, from 100mm to 180mm, and with both flat and curved surface designs. This diversity allows the grinding discs to adapt to different working conditions. For example, the smaller 100mm discs are ideal for precision work in tight spaces, while the larger 180mm discs are more suitable for large - scale material removal. The flat - surface design is perfect for general grinding and polishing, while the curved - surface design can be used for special - shaped workpieces, providing users with more options to meet their specific needs.

Quality control is a top priority for Youde Superhard Tools. Each grinding disc undergoes meticulous manual measurement and batch - by - batch inspection. This attention to detail ensures that every product meets the highest standards of precision. The brand's dedication to quality control not only guarantees the performance of the grinding discs but also reflects its commitment to providing customers with reliable and high - quality products.

In conclusion, Youde Superhard Tools' brazed diamond grinding discs offer a comprehensive solution for various hard - material processing needs. With their high safety, long - lasting durability, and strict quality control, they are the ideal choice for industrial operators. If you are looking for a reliable and efficient grinding solution, don't miss out on Youde's brazed diamond grinding discs. Discover more about our products and start your worry - free grinding journey today!